Actuator

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a “mover”.

An actuator requires a control signal and a source of energy. The control signal is relatively low energy and may be electric voltage or current, pneumatic or hydraulic pressure, or even human power. Its main energy source may be an electric current, hydraulic fluid pressure, or pneumatic pressure. When it receives a control signal, an actuator responds by converting the signal’s energy into mechanical motion.

An actuator is the mechanism by which a control system acts upon an environment. The control system can be simple (a fixed mechanical or electronic system), software-based (e.g. a printer driver, robot control system), a human, or any other input.

History

The history of the pneumatic actuation system and the hydraulic actuation system dates to around the time of World War II (1938). It was first created by Xhiter Anckeleman (pronounced ‘Ziter’) who used his knowledge of engines and brake systems to come up with a new solution to ensure that the brakes on a car exert the maximum force, with the least possible wear and tear.

Hydraulic

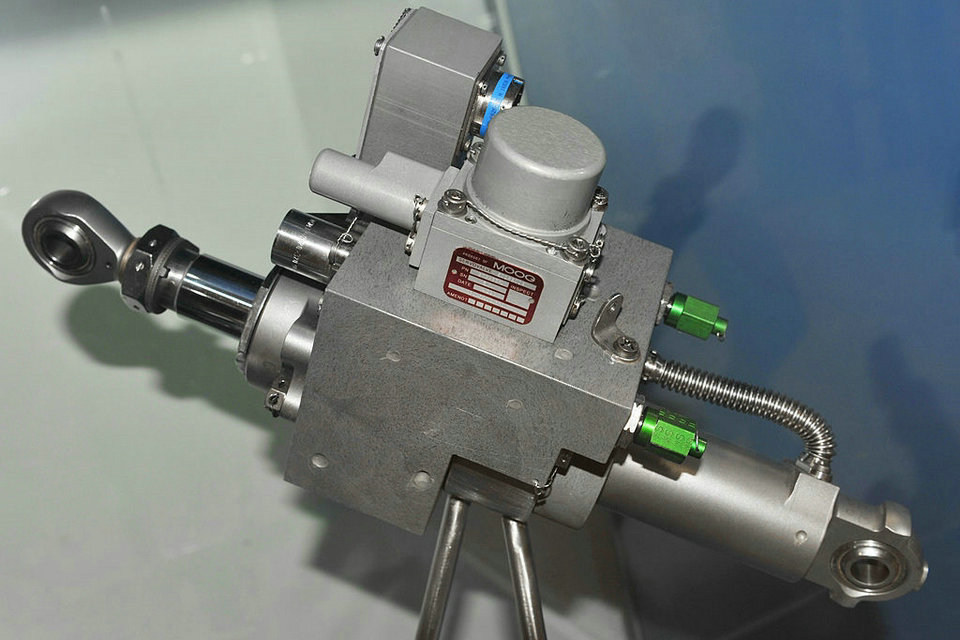

A hydraulic actuator consists of cylinder or fluid motor that uses hydraulic power to facilitate mechanical operation. The mechanical motion gives an output in terms of linear, rotatory or oscillatory motion. As liquids are nearly impossible to compress, a hydraulic actuator can exert a large force. The drawback of this approach is its limited acceleration.

The hydraulic cylinder consists of a hollow cylindrical tube along which a piston can slide. The term single acting is used when the fluid pressure is applied to just one side of the piston. The piston can move in only one direction, a spring being frequently used to give the piston a return stroke. The term double acting is used when pressure is applied on each side of the piston; any difference in pressure between the two sides of the piston moves the piston to one side or the other.

Pneumatic

Pneumatic actuators enable considerable forces to be produced from relatively small pressure changes. A pneumatic actuator converts energy formed by vacuum or compressed air at high pressure into either linear or rotary motion. Pneumatic energy is desirable for main engine controls because it can quickly respond in starting and stopping as the power source does not need to be stored in reserve for operation. Moreover, pneumatic actuators are safer, cheaper, and often more reliable and powerful than other actuators. These forces are often used with valves to move diaphragms to affect the flow of air through the valve.

Electric

An electric actuator is powered by a motor that converts electrical energy into mechanical torque. The electrical energy is used to actuate equipment such as multi-turn valves. Additionally, a brake is typically installed above the motor to prevent the media from opening valve. If no brake is installed, the actuator will uncover the opened valve and rotate it back to its closed position. If this continues to happen, the motor and actuator will eventually become damaged. It is one of the cleanest and most readily available forms of actuator because it does not directly involve oil or other fossil fuels.

The structure of an electric actuator is simple compared to that of hydraulic and pneumatic actuators, since they only require electrical power as an energy source. As electric cables are used to transmit electricity and signals, it is highly versatile and there are virtually no restrictions regarding the distance between the power source and the actuator.

There is a large number of models and it is easy to use them with standardized electric motors depending on the application. In most cases it is necessary to use reducers, because the motors are of continuous operation.

Use of an electric piston to drive a small valve.

The simplest form for the drive with a piston, would be the installation of a lever integral with a hinge attached to a surface parallel to the axis of the drive piston and the threaded entries.

There are Muscular Wires®, which allow silent movements without motors. It is the most innovative technology for robotics and automation, as well as for the implementation of small actuators.

There are also electroactive polymers, PEA (for its acronym in Spanish) or EAP (for its acronym in English), which are polymers that usually change shape or size when stimulated by an electric field. They are mainly used as actuators, sensors, or the generation of artificial muscles to be used in robotics and prosthetics.

Twisted and coiled polymer (TCP) or supercoiled polymer (SCP)

Twisted and coiled polymer (TCP) actuator also known as supercoiled polymer (SCP) actuator is a coiled polymer that can be actuated by electric power. A TCP actuator look like a helical spring. TCP actuators are usually made from silver coated Nylon. TCP actuators can also be made from other electrical conductance coat such as gold. TCP actuator should be under a load to keep the muscle extended. The electrical energy transforms to thermal energy due to electrical resistance, which is also known as Joule heating, Ohmic heating, and resistive heating. As the temperature of the TCP actuator increases by Joule heating, the polymer contracts and it causes the actuator contraction.

Piezoelectric actuators

Are those devices that produce movement (displacement) taking advantage of the physical phenomenon of piezoelectricity. Actuators that use this effect have been available for approximately 20 years and have changed the world of positioning. The precise movement that results when an electric field is applied to the material is of great value for nanopositioning.

It is possible to distinguish the following types:

Stack type

Of type “Flexure”

Combined with high-ranking motorized positioning system

Thermal or magnetic

Actuators which can be actuated by applying thermal or magnetic energy have been used in commercial applications. Thermal actuators tend to be compact, lightweight, economical and with high power density. These actuators use shape memory materials (SMMs), such as shape-memory alloys (SMAs) or magnetic shape-memory alloys (MSMAs). Some popular manufacturers of these devices are Finnish Modti Inc., American Dynalloy and Rotork.

Mechanical

A mechanical actuator functions to execute movement by converting one kind of motion, such as rotary motion, into another kind, such as linear motion. An example is a rack and pinion. The operation of mechanical actuators is based on combinations of structural components, such as gears and rails, or pulleys and chains.

Electronic actuators

Electronic actuators are also widely used in mechatronic devices, such as robots. The brushless AC servomotors will be used in the future as precise positioning actuators due to the demand for operation without as many maintenance hours as nuclear energy.

Hydraulic actuators

The hydraulic actuators, which are the oldest, can be classified according to the operation form, operate on the basis of pressurized fluids. There are three major groups:

hydraulic cylinder

hydraulic engine

hydraulic swing motor

Hydraulic cylinder

According to its function we can classify the hydraulic cylinders in 2 types: simple effect and double action. In the first type, hydraulic force is used to push and an external force, different, to contract. The second type uses hydraulic power to perform both actions. The steering control is carried out by means of a solenoid. Inside they have a spring that changes its elastic constant with the passage of current. That is, if current flows through the electric piston it can be easily extended.

Dynamic pressure cylinder

Carry the load at the base of the cylinder. Manufacturing costs are generally low since there are no parts that slip inside the cylinder.

Single effect cylinder

The bar is only at one end of the piston, which is contracted by springs or by the same gravity. The load can be placed only on one end of the cylinder.

Double effect cylinder

The load can be placed on either side of the cylinder. A horizontal pulse is generated due to the difference in pressure between the ends of the piston

Telescopic cylinder

The multi-stage tube type bar is pushed successively as it is applied to the pressurized oil cylinder. A relatively long stroke can be achieved compared to the length of the cylinder

Hydraulic motor

In the hydraulic motors the rotary movement is generated by the pressure. These engines can be classified into two large groups: The first is a rotary type in which the gears are driven directly by oil under pressure, and the second, oscillating type, the rotary movement is generated by the oscillatory action of a piston or hammer; This type has higher demand due to its greater efficiency. Below is the classification of this type of engine

Gear motor

Vane type rotary motor

Propeller motor

Hydraulic motor Eccentric cam motor

Axial piston

Oscillating type Motor with inclined axis

Gear motor: The pressure oil flows from the inlet acting on the toothed face of each gear generating torque in the direction of the arrow. The motor structure is simple, so it is highly recommended for use in high speed operations.

Motor with inclined axis piston

The pressurized oil that flows from the inlet pushes the piston against the flange and the resulting force in the radial direction causes the shaft and the cylinder block to rotate in the direction of the arrow. This type of motor is very convenient for high-pressure and high-speed applications. It is possible to modify its capacity by changing the angle of inclination of the axis.

Oscillating motor with axial piston

Its function is to absorb a certain volume of fluid under pressure and return it to the circuit when it needs it.

Pneumatic actuators

The mechanisms that convert the energy of the compressed air into mechanical work are called pneumatic actuators. Although in essence they are identical to the hydraulic actuators, the compression range is lower in this case, in addition to that there is a small difference in terms of use and in regard to the structure, motivated to the elements of power supply (air) are different from those used in hydraulic cylinders.

In this classification appear the bellows and diaphragms, which use compressed air and are considered as simple effect actuators, and also the artificial rubber muscles, which lately have received much attention.

Simple effect

Pneumatic cylinder

Double effect pneumatic actuator

Linear actuator of double effect without shank

With gear and rack

With gear and double zipper

Pneumatic motor with vane

With piston

With a weather vane at the same time

Multivalve

Rotary engine with piston

From vertical slot

Plunger

Bellows, diaphragm and artificial muscle

Single effect cylinder

Rotating pallets

They are motor elements designed to provide a limited turn in an output shaft. The air pressure acts directly on one or two blades printing a turning movement. These do not exceed 270 ° and those of double pallet do not exceed 90 °.

Parts of an actuator

“Safety key” system: This method of safety key for retaining the actuator covers uses a flexible cylindrical stainless steel tape in a machine-machined sliding groove. This eliminates the concentration of stresses caused by loads centered on the screws of the covers and helicoils. The safety keys greatly increase the strength of the actuator assembly and provide a safety lock against dangerous uncoupling.

Pinion with slot: This groove in the upper part of the pinion provides a self-centering, direct transmission for position indicators and position switches, eliminating the use of coupling flanges. (Under the Namur norm).

Splicing bearings: These spliced and threaded splicing bearings serve to simplify the coupling of fittings to be mounted on the top. (Under ISO 5211 and VDI standards).

Large air pass: The internal ducts for the extra large air passage allow a quick operation and avoid the blocking of them.

Muñoneras: A new design and maximum durability, permanently lubricated, corrosion resistant and easy to replace, extends the life of the actuator in the most severe applications.

Construction: Maximum force must be provided against dents, shocks and fatigue. Its rack and pinion must be of great caliber, it must be machined with high precision machinery, and eliminates the game to be able to obtain precise positions.

Ceramigard: Strong surface, resistant to corrosion, similar to ceramic. Protects all parts of the actuator against wear and corrosion.

Coating: A double coating, to provide extra protection against aggressive environments.

Coupling: Coupling or uncoupling of spring-loaded replacement modules, or safety in case of air pressure failure.

Stroke adjustment screws: Provides adjustments for the rotation of the pinion in both directions of travel; what is essential for every quarter-turn valve.

Radial and load-bearing sprockets of the pinion: Replaceable trunnions that protect against vertical loads. Radial mufflers support all radial load.

Pinion seals – upper and lower: The pinion seals are positioned to minimize every possible gap, to protect against corrosion.

Indestructible safety springs in case of failure: These springs are designed and manufactured to never fail and are subsequently protected against corrosion. The springs are classified and assigned in a particular way to compensate for the loss of memory to which every spring is subject; for true confidence in case of failure in the air supply.

The most usual actuators are:

Pneumatic and hydraulic cylinders. They perform linear movements.

Motors (turning actuators) pneumatic and hydraulic. They perform turning movements by means of hydraulic or pneumatic energy.

Valves. There are direct control, motorized, electropneumatic, etc. They are used to regulate the flow of gases and liquids.

Heating resistors. They are used to heat.

Electric motors. The most used are induction, continuous, brushless and step by step.

Pumps, compressors and fans. Moved generally by electric induction motors.

3D printed soft actuators

Soft actuators are being developed to handle fragile objects like fruit harvesting in agriculture or manipulating the internal organs in biomedicine that has always been a challenging task for robotics. Unlike conventional actuators, soft actuators produce flexible motion due to the integration of microscopic changes at the molecular level into a macroscopic deformation of the actuator materials.

The majority of the existing soft actuators are fabricated using multistep low yield processes such as micro-moulding, solid freeform fabrication, and mask lithography. However, these methods require manual fabrication of devices, post processing/assembly, and lengthy iterations until maturity in the fabrication is achieved. To avoid the tedious and time-consuming aspects of the current fabrication processes, researchers are exploring an appropriate manufacturing approach for effective fabrication of soft actuators. Therefore, special soft systems that can be fabricated in a single step by rapid prototyping methods, such as 3D printing, are utilized to narrow the gap between the design and implementation of soft actuators, making the process faster, less expensive, and simpler. They also enable incorporation of all actuator components into a single structure eliminating the need to use external joints, adhesives, and fasteners. These result in a decrease in the number of discrete parts, post-processing steps, and fabrication time.

3D printed soft actuators are classified into two main groups namely “semi 3D printed soft actuators” and “3D printed soft actuators”. The reason for such classification is to distinguish between the printed soft actuators that are fabricated by means of 3D printing process in whole and the soft actuators whose parts are made by 3D printers and post processed subsequently. This classification helps to clarify the advantages of 3D printed soft actuators over the semi 3D printed soft actuators due to their capability of operating without the need of any further assembly.

Shape memory polymer (SMP) actuators are the most similar to our muscles, providing a response to a range of stimuli such as light, electrical, magnetic, heat, pH, and moisture changes. They have some deficiencies including fatigue and high response time that have been improved through the introduction of smart materials and combination of different materials by means of advanced fabrication technology. The advent of 3D printers has made a new pathway for fabricating low-cost and fast response SMP actuators. The process of receiving external stimuli like heat, moisture, electrical input, light or magnetic field by SMP is referred to as shape memory effect (SME). SMP exhibits some rewarding features such a low density, high strain recovery, biocompatibility, and biodegradability.

Photopolymer/light activated polymers (LAP) are another type of SMP that are activated by light stimuli. The LAP actuators can be controlled remotely with instant response and, without any physical contact, only with the variation of light frequency or intensity.

A need for soft, lightweight and biocompatible soft actuators in soft robotics has influenced researchers for devising pneumatic soft actuators because of their intrinsic compliance nature and ability to produce muscle tension.

Polymers such as dielectric elastomers (DE), ionic polymer metal composites (IPMC), ionic electroactive polymers, polyelectrolyte gels, and gel-metal composites are common materials to form 3D layered structures that can be tailored to work as soft actuators. EAP actuators are categorized as 3D printed soft actuators that respond to electrical excitation as deformation in their shape.

Examples and applications

In engineering, actuators are frequently used as mechanisms to introduce motion, or to clamp an object so as to prevent motion. In electronic engineering, actuators are a subdivision of transducers. They are devices which transform an input signal (mainly an electrical signal) into some form of motion.

Examples of actuators

Comb drive

Digital micromirror device

Electric motor

Electroactive polymer

Hydraulic cylinder

Piezoelectric actuator

Pneumatic actuator

Screw jack

Servomechanism

Solenoid

Stepper motor

Shape-memory alloy

Thermal bimorph

Hydraulic actuators

Circular to linear conversion

Motors are mostly used when circular motions are needed, but can also be used for linear applications by transforming circular to linear motion with a lead screw or similar mechanism. On the other hand, some actuators are intrinsically linear, such as piezoelectric actuators. Conversion between circular and linear motion is commonly made via a few simple types of mechanism including:

Screw: Screw jack, ball screw and roller screw actuators all operate on the principle of the simple machine known as the screw. By rotating the actuator’s nut, the screw shaft moves in a line. By moving the screw shaft, the nut rotates.

Wheel and axle: Hoist, winch, rack and pinion, chain drive, belt drive, rigid chain and rigid belt actuators operate on the principle of the wheel and axle. By rotating a wheel/axle (e.g. drum, gear, pulley or shaft) a linear member (e.g. cable, rack, chain or belt) moves. By moving the linear member, the wheel/axle rotates.

Virtual instrumentation

In virtual instrumentation, actuators and sensors are the hardware complements of virtual instruments.

Performance metrics

Performance metrics for actuators include speed, acceleration, and force (alternatively, angular speed, angular acceleration, and torque), as well as energy efficiency and considerations such as mass, volume, operating conditions, and durability, among others.

Force

When considering force in actuators for applications, two main metrics should be considered. These two are static and dynamic loads. Static load is the force capability of the actuator while not in motion. Conversely, the dynamic load of the actuator is the force capability while in motion.

Speed

Speed should be considered primarily at a no-load pace, since the speed will invariably decrease as the load amount increases. The rate the speed will decrease will directly correlate with the amount of force and the initial speed.

Operating conditions

Actuators are commonly rated using the standard IP Code rating system. Those that are rated for dangerous environments will have a higher IP rating than those for personal or common industrial use.

Durability

This will be determined by each individual manufacturer, depending on usage and quality.

Source from Wikipedia