Stereolithography (SLA or SL; also known as stereolithography apparatus, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photopolymerization, a process by which light causes chains of molecules to link, forming polymers. Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create things such as prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive.

History

Stereolithography or “SLA” printing is an early and widely used 3D printing technology. In the early 1980s, Japanese researcher Hideo Kodama first invented the modern layered approach to stereolithography by using ultraviolet light to cure photosensitive polymers. In 1984, just before Chuck Hull filed his own patent, Alain Le Mehaute, Olivier de Witte and Jean Claude André filed a patent for the stereolithography process. The French inventors’ patent application was abandoned by the French General Electric Company (now Alcatel-Alsthom) and CILAS (The Laser Consortium). Le Mehaute believes that the abandonment reflects a problem with innovation in France.

However, the term “stereolithography” was coined in 1984 by Chuck Hull when he filed his patent for the process. Chuck Hull patented stereolithography as a method of creating 3D objects by successively “printing” thin layers of an object using a medium curable by ultraviolet light, starting from the bottom layer to the top layer. Hull’s patent described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with a liquid photopolymer. The beam is focused onto the surface of the liquid photopolymer, creating each layer of the desired 3D object by means of crosslinking (generation of intermolecular bonds in polymers). It was invented with the intent of allowing engineers to create prototypes of their designs in a more time effective manner. After the patent was granted in 1986, Hull co-founded the world’s first 3D printing company, 3D Systems, to commercialize it.

Stereolithography’s success in the automotive industry allowed 3D printing to achieve industry status and the technology continues to find innovative uses in many fields of study. Attempts have been made to construct mathematical models of stereolithography processes and to design algorithms to determine whether a proposed object may be constructed using 3D printing.

Technology

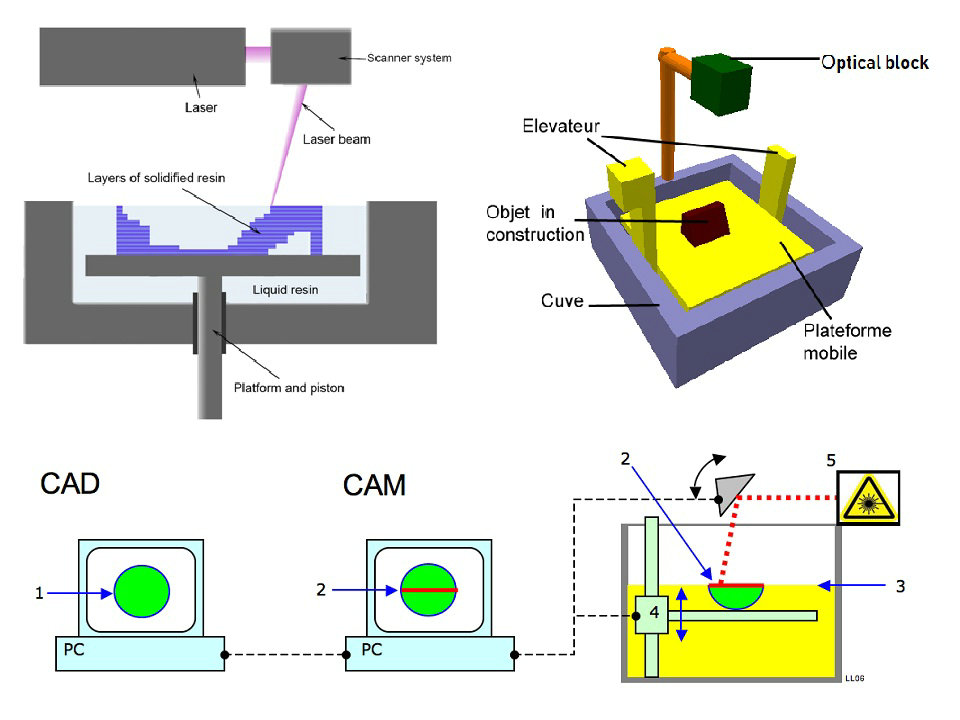

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. Then, the build platform lowers one layer and a blade recoats the top of the tank with resin. This process is repeated for each layer of the design until the 3D object is complete. Completed parts must be washed with a solvent to clean wet resin off their surfaces.

It is also possible to print objects “bottom up” by using a vat with a transparent bottom and focusing the UV or deep-blue polymerization laser upward through the bottom of the vat. An inverted stereolithography machine starts a print by lowering the build platform to touch the bottom of the resin-filled vat, then moving upward the height of one layer. The UV laser then writes the bottom-most layer of the desired part through the transparent vat bottom. Then the vat is “rocked”, flexing and peeling the bottom of the vat away from the hardened photopolymer; the hardened material detaches from the bottom of the vat and stays attached to the rising build platform, and new liquid photopolymer flows in from the edges of the partially built part. The UV laser then writes the second-from-bottom layer and repeats the process. An advantage of this bottom-up mode is that the build volume can be much bigger than the vat itself, and only enough photopolymer is needed to keep the bottom of the build vat continuously full of photopolymer. This approach is typical of desktop SLA printers, while the right-side-up approach is more common in industrial systems.

Stereolithography requires the use of supporting structures which attach to the elevator platform to prevent deflection due to gravity, resist lateral pressure from the resin-filled blade, or retain newly created sections during the “vat rocking” of bottom up printing. Supports are typically created automatically during the preparation of CAD models and can also be made manually. In either situation, the supports must be removed manually after printing.

Principle

A light curing (photopolymer) plastic, for example acrylic, epoxy or vinylester resin, is cured by a laser in thin layers (standard layer thickness in the range 0.05-0.25 mm, in micro stereolithography also up to 1-micron layers). The procedure is carried out in a bath filled with the base monomers of the photosensitive resin. After each step, the workpiece is lowered a few millimeters into the liquid and returned to a position which is lower than the previous one by the amount of a layer thickness. The liquid plastic over the part is then passed through a squeegee, equally distributed. Then a laser, controlled by a computer through moving mirrors, travels on the new layer over the surfaces that are to be cured. After curing, the next step takes place, gradually creating a three-dimensional model.

In microstereolithography, no support structures are required, and in many cases postcuring is also eliminated. In stereolithography processes for large components this is different, since the laser-hardened resin is still relatively soft and also certain form elements (eg overhangs) are to be securely fixed during the construction process. For this purpose, support structures are also built in the production. After the construction process, the platform with the part (s) is moved out of the container. After draining the uncured resin, the model is removed from the platform, stripped of support structures, washed with solvents, and fully cured in a cabinet under UV light.

Another method that also uses photopolymerization to make physical objects is Solid Ground Curing (SGC). Each layer is cured by UV light, whereby a light mask must be printed in a photoplotter for each layer. However, this method, which was used particularly in the plants of the company Cubital (Israel), has lost in recent years, very much in importance.

The process begins with a model of the object to be manufactured. This model is achieved through a program of CAD or acquiring digital an existing object we want to reproduce.

The model once drawn must be exported in a standard format, the STL format (for STereoLithography). This format was originally designed to communicate with stereolithography devices but is now used in other areas. This is a de facto industry standard. This format describes models in the form of contiguous triangular surfaces.

The STL file is transmitted to the stereolithography device which integrates a PLC or, more often, PC type control module.

The model (in 3D) is divided into slices (2D) of fixed thickness. This thickness is chosen by the operator and determines the resolution of the restitution. This parameter therefore determines the accuracy of the object that will be produced.

The object is produced.

Features

Existing 3D CAD data is converted to STL format. These data are sent to the stereolithography service providers, who then add the possibly necessary support structures.

After the construction site has been determined, the generation of the geometric control data required for the installation, the so-called “slicing”, takes place.

These data are sent to the manufacturing system and form the basis for controlling the laser beam on the bath surface.

Within a few hours, you get a real model of the parts that are virtually available in the CAD.

Stereolithography allows for high precision (typically 0.1mm, much lower down to 1 micron per layer for RMPD) with fine structures and thin wall thicknesses.

Since a model is built in a liquid, supporting structures that have to be removed are required for overhanging parts in the case of large components. In contrast to other rapid prototyping methods, however, the support structure consists of the same material as the component and must therefore be mechanically removed (since a connection to the component can not be avoided).

In most cases, the model created by stereolithography has to be cured after removal from the machine in a UV light cabinet.

In recent years, technical developments have been made that combine multi-jet modeling with basic principles of stereolithography. As a support material serves a wax material, which is liquefied by heating. The component itself is produced analogously to stereolithography from a photopolymer. Both materials are applied via a modified printhead (similar to inkjet printers). In addition, a light source provides the exposure and thus the curing of the photopolymer. Unlike RP stereolithography systems, these systems can also be used in the office and are significantly cheaper with prices starting at around 50,000 euros.

Another new technical development is Continuous Liquid Interface Production (CLIP).

In two-photon lithography, a 100 nanometer diameter UV focus at 5 meters per second is directed three-dimensionally through the volume of the liquid resin. It is therefore not cured starting from the surface of the liquid resin. So that the UV focus has only a small extent in the propagation direction of the radiation, a shallow depth of field and a large aperture is required. Because the two-photon absorption has a quadratic dependence on the intensity of the light, the hardening area of the resin is sharply demarcated.

Application

Compared to models made by other generative manufacturing techniques such as selective laser melting, a stereolithography model is brittle, which limits its application. The necessary support structures for undercuts also limit the geometry of the component. The stereolithography process is therefore used in product development in the creation of prototypes (concept, geometry, visual, functional models) in mechanical engineering, in particular in the automotive industry and in medicine. An increasing trend is expected in the next few years in the direct production of end products using stereolithography equipment (Rapid manufacturing). Application examples that already play a role in daily life include the production of individual cases for hearing aids using stereolithography and the lab-on-chip systems manufactured by microTEC.

Further application examples are casting models and architectural models.

Medical modeling

Stereolithographic models have been used in medicine since the 1990s, for creating accurate 3D models of various anatomical regions of a patient, based on data from computer scans. Medical modelling involves first acquiring a CT, MRI, or other scan. This data consists of a series of cross sectional images of the human anatomy. In these images different tissues show up as different levels of grey. Selecting a range of grey values enables specific tissues to be isolated. A region of interest is then selected and all the pixels connected to the target point within that grey value range are selected. This enables a specific organ to be selected. This process is referred to as segmentation. The segmented data may then be translated into a format suitable for stereolithography. While stereolithography is normally accurate, the accuracy of a medical model depends on many factors, especially the operator performing the segmentation correctly. There are potential errors possible when making medical models using stereolithography but these can be avoided with practice and well trained operators.

Stereolithographic models are used as an aid to diagnosis, preoperative planning and implant design and manufacture. This might involve planning and rehearsing osteotomies, for example. Surgeons use models to help plan surgeries but prosthetists and technologists also use models as an aid to the design and manufacture of custom-fitting implants. For instance, medical models created through stereolithography can be used to help in the construction of Cranioplasty plates.

Prototyping

Stereolithography is often used for prototyping parts. For a relatively low price, Stereolithography can produce accurate prototypes, even of irregular shapes. Businesses can use those prototypes to assess the design of their product or as publicity for the final product.

Advantages and disadvantages

Advantages

One of the advantages of stereolithography is its speed; functional parts can be manufactured within a day. The length of time it takes to produce a single part depends upon the complexity of the design and the size. Printing time can last anywhere from hours to more than a day. Prototypes and designs made with stereolithography are strong enough to be machined and can also be used to make master patterns for injection molding or various metal casting processes.

Disadvantages

Although stereolithography can be used to produce virtually any synthetic design, it is often costly; common photopolymers can cost about US$800 per gallon and SLA machines can cost US$250,000. Since 2012, however, public interest in 3D printing has inspired the design of several consumer SLA machines which can cost US$3,500 or less, such as the Form 2 by Formlabs or the Nobel 1.0 by XYZPrinting.

The different types of stereolithography

Several techniques are used to produce the prototypes quickly.

It should be noted now that the border with 3D printing is crossed to the point that the two technologies merge in a very diversified set.

Light Curing (ALS)

Method

The curing is the first rapid prototyping process to be developed in the 1980 SLA name (for Stereolithography Apparatus) was given. It is based on the properties of certain resins to polymerize under the effect of light and heat.

The resin used is generally a mixture of acrylate or epoxy monomers and a photoinitiator. The role of the photoinitiator is, as its name suggests, to initiate the polymerization of the material under the effect of light.

In this process, a mobile platform is immersed in a tank of liquid resin. This platform supports the model being manufactured. The platform is positioned at a depth H below the level of the resin. A fixed laser and a beam control device overhang the platform. The control of the beam direction is carried out using deflectors which are very precise mirrors (very flat) mounted on galvanometers. The use of two of these control devices makes it possible to direct the beam at any point of the platform.

The slices constituting the model are then processed one by one: the laser beam sweeps the liquid resin surface according to the shape of the slice defined by computer.

Under the effect of light, the photoinitiator forms a radical and the monomers are instantly bridged to each other forming a solid polymer.

The platform then descends from a height h (The height h is the resolution that was chosen for the production of the object) and the process is renewed for each slice. The two-dimensional objects thus produced are superimposed to produce the complete structure.

Once completed, the model is removed from the tank and the unpolymerized mixture is dissolved in a suitable solvent.

The last step often consists in baking the object in order to harden it, depending on the resin used.

Limitations and advantages

Problem of “trapped volumes”. The principle being to superimpose successive layers of matter; the material present in the non-solidified zones is not eliminated and therefore remains present in the model. If it is a hermetically sealed volume, the material is called “trapped”. Example: the modeling of an eggshell.

Advantage: Advances in technology now make it possible to work in high resolution and produce complex objects with very thin parts (0.005 mm) in less than 24 hours. 3D laser micro-printing machines, developed since the beginning of the decade, also make it possible to achieve resolutions up to 100 times higher (<0.1 μm), thanks to a stereolithography process called "polymerization with two photons ".

Uses

For a long time, this method was reserved for the creation of prototypes because of the fragility of objects, unusable as such because of their low mechanical strength: they are used to form molds.

In the early 2000s, the work led by M.Chartier (SPCTS) made it possible to use this method to produce ceramic parts by mixing ceramic powders (alumina, zirconia, hydroxyapatite, etc.) with a paste made of resin photosensitive. The suspension once insolated forms a polymer network trapping the mineral particles. After polymerization by laser, a heat treatment (debinding and then sintering) of the object makes it possible to obtain a dense ceramic.

Application areas:

The properties of the ceramics obtained by this technique are equivalent to the traditional processes (casting, pressing...), the objects are therefore usable as such.

Foundry models, prototypes for form validation, medical prostheses, small series of very complex shapes for all types of industries...

In paleontology, this technique makes it possible, from conventional CT or micro-CT scans, to reconstruct and study fine and inaccessible structures (insects in amber, bony labyrinth of the inner ear). This technique allows especially very large enlargements for the change of scale.

Source from Wikipedia