A quantum dot solar cell (QDSC ) is a solar cell design that uses quantum dots as the absorbing photovoltaic material. It attempts to replace bulk materials such as silicon, copper indium gallium selenide (CIGS) or CdTe. Quantum dots have bandgaps that are tunable across a wide range of energy levels by changing their size. In bulk materials, the bandgap is fixed by the choice of material(s). This property makes quantum dots attractive for multi-junction solar cells, where a variety of materials are used to improve efficiency by harvesting multiple portions of the solar spectrum.

As of 2016, efficiency exceeds 10%.

Background

Solar cell concepts

In a conventional solar cell, light is absorbed by a semiconductor, producing an electron-hole (e-h) pair; the pair may be bound and is referred to as an exciton. This pair is separated by an internal electric field (present in p-n junctions or Schottky diodes) and the resulting flow of electrons and holes creates electric current. The internal electric field is created by doping one part of semiconductor interface with atoms that act as electron donors (n-type doping) and another with electron acceptors (p-type doping) that results in a p-n junction. Generation of an e-h pair requires that the photons have energy exceeding the bandgap of the material. Effectively, photons with energies lower than the bandgap do not get absorbed, while those that are higher can quickly (within about 10−13 s) thermalize to the band edges, reducing output. The former limitation reduces current, while the thermalization reduces the voltage. As a result, semiconductor cells suffer a trade-off between voltage and current (which can be in part alleviated by using multiple junction implementations). The detailed balance calculation shows that this efficiency can not exceed 31% if one uses a single material for a solar cell.

Numerical analysis shows that the 31% efficiency is achieved with a bandgap of 1.3-1.4 eV, corresponding to light in the near infrared spectrum. This band gap is close to that of silicon (1.1 eV), one of the many reasons that silicon dominates the market. However, silicon’s efficiency is limited to about 29%. It is possible to improve on a single-junction cell by vertically stacking cells with different bandgaps – termed a “tandem” or “multi-junction” approach. The same analysis shows that a two layer cell should have one layer tuned to 1.64 eV and the other to 0.94 eV, providing a theoretical performance of 44%. A three-layer cell should be tuned to 1.83, 1.16 and 0.71 eV, with an efficiency of 48%. An “infinity-layer” cell would have a theoretical efficiency of 86%, with other thermodynamic loss mechanisms accounting for the rest.

Traditional (crystalline) silicon preparation methods do not lend themselves to this approach due to lack of bandgap tunability. Thin-films of amorphous silicon, which due to a relaxed requirement in crystal momentum preservation can achieve direct bandgaps and intermixing of carbon, can tune the bandgap, but other issues have prevented these from matching the performance of traditional cells. Most tandem-cell structures are based on higher performance semiconductors, notably indium gallium arsenide (InGaAs). Three-layer InGaAs/GaAs/InGaP cells (bandgaps 0.94/1.42/1.89 eV) hold the efficiency record of 42.3% for experimental examples.

However, the QDSCs suffer from weak absorption and the contribution of the light absorption at room temperature is marginal. This can be addressed by utilizing multibranched Au nanostars.

Quantum dots

Quantum dots are semiconducting particles that have been reduced below the size of the Exciton Bohr radius and due to quantum mechanics considerations, the electron energies that can exist within them become finite, much alike energies in an atom. Quantum dots have been referred to as “artificial atoms”. These energy levels are tuneable by changing their size, which in turn defines the bandgap. The dots can be grown over a range of sizes, allowing them to express a variety of bandgaps without changing the underlying material or construction techniques. In typical wet chemistry preparations, the tuning is accomplished by varying the synthesis duration or temperature.

The ability to tune the bandgap makes quantum dots desirable for solar cells. Single junction implementations using lead sulfide (PbS) colloidal quantum dots (CQD) have bandgaps that can be tuned into the far infrared, frequencies that are typically difficult to achieve with traditional solar cells. Half of the solar energy reaching the Earth is in the infrared, most in the near infrared region. A quantum dot solar cell makes infrared energy as accessible as any other.

Moreover, CQD offer easy synthesis and preparation. While suspended in a colloidal liquid form they can be easily handled throughout production, with a fumehood as the most complex equipment needed. CQD are typically synthesized in small batches, but can be mass-produced. The dots can be distributed on a substrate by spin coating, either by hand or in an automated process. Large-scale production could use spray-on or roll-printing systems, dramatically reducing module construction costs.

Production

Early examples used costly molecular beam epitaxy processes. However, the lattice mismatch results in accumulation of strain and thus generation of defects, restricting the number of stacked layers. Droplet epitaxy growth technique shows its advantages on the fabrication of strain-free QDs. Alternatively, less expensive fabrication methods were later developed. These use wet chemistry (for CQD) and subsequent solution processing. Concentrated nanoparticle solutions are stabilized by long hydrocarbon ligands that keep the nanocrystals suspended in solution.

To create a solid, these solutions are cast down[clarification needed] and the long stabilizing ligands are replaced with short-chain crosslinkers. Chemically engineering the nanocrystal surface can better passivate the nanocrystals and reduce detrimental trap states that would curtail device performance by means of carrier recombination.[clarification needed] This approach produces an efficiency of 7.0%.

A more recent study uses different ligands for different functions by tuning their relative band alignment to improve the performance to 8.6%. The cells were solution-processed in air at room-temperature and exhibited air-stability for more than 150 days without encapsulation.

In 2014 the use of iodide as a ligand that does not bond to oxygen was introduced. This maintains stable n- and p-type layers, boosting the absorption efficiency, which produced power conversion efficiency up to 8%.

History

The idea of using quantum dots as a path to high efficiency was first noted by Burnham and Duggan in 1990. At the time, the science of quantum dots, or “wells” as they were known, was in its infancy and early examples were just becoming available.

DSSC efforts

Another modern cell design is the dye-sensitized solar cell, or DSSC. DSSCs use a sponge-like layer of TiO

2 as the semiconductor valve as well as a mechanical support structure. During construction, the sponge is filled with an organic dye, typically ruthenium-polypyridine, which injects electrons into the titanium dioxide upon photoexcitation. This dye is relatively expensive, and ruthenium is a rare metal.

Using quantum dots as an alternative to molecular dyes was considered from the earliest days of DSSC research. The ability to tune the bandgap allowed the designer to select a wider variety of materials for other portions of the cell. Collaborating groups from the University of Toronto and École Polytechnique Fédérale de Lausanne developed a design based on a rear electrode directly in contact with a film of quantum dots, eliminating the electrolyte and forming a depleted heterojunction. These cells reached 7.0% efficiency, better than the best solid-state DSSC devices, but below those based on liquid electrolytes.

Multi-junction

Cadmium telluride (CdTe) is used for cells that absorb multiple frequencies. A colloidal suspension of these crystals is spin-cast onto a substrate such as a thin glass slide, potted in a conductive polymer. These cells did not use quantum dots, but shared features with them, such as spin-casting and the use of a thin film conductor. At low production scales quantum dots are more expensive than mass-produced nanocrystals, but cadmium and telluride are rare and highly toxic metals subject to price swings.

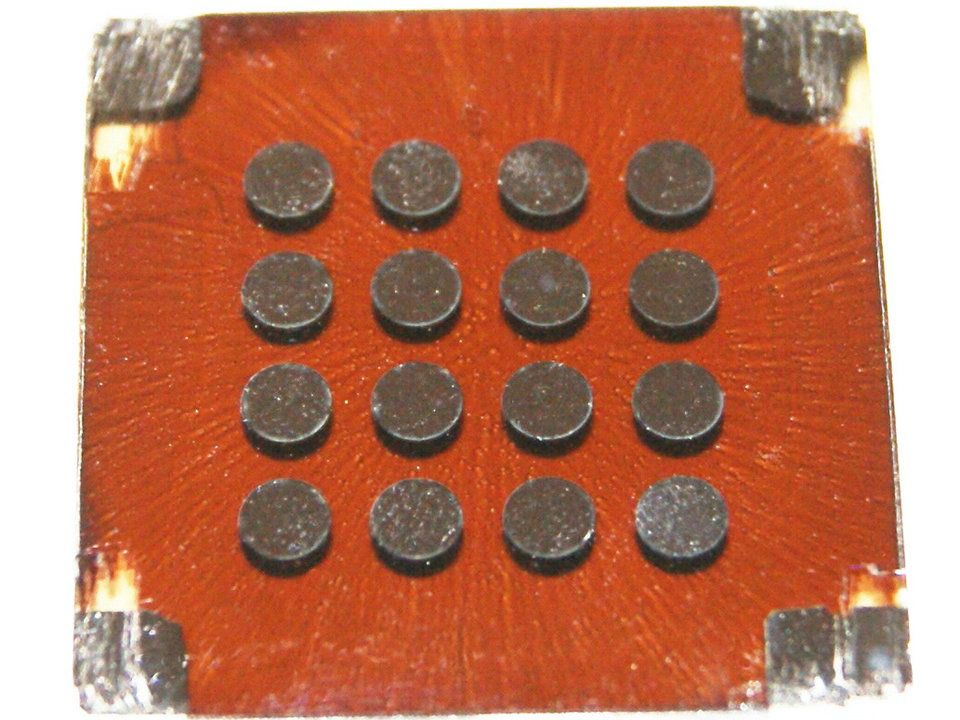

The Sargent Group[who?] used lead sulfide as an infrared-sensitive electron donor to produce then record-efficiency IR solar cells. Spin-casting may allow the construction of “tandem” cells at greatly reduced cost. The original cells used a gold substrate as an electrode, although nickel works just as well.

Hot-carrier capture

Another way to improve efficiency is to capture the extra energy in the electron when emitted from a single-bandgap material. In traditional materials like silicon, the distance from the emission site to the electrode where they are harvested is too far to allow this to occur; the electron will undergo many interactions with the crystal materials and lattice, giving up this extra energy as heat. Amorphous thin-film silicon was tried as an alternative, but the defects inherent to these materials overwhelmed their potential advantage. Modern thin-film cells remain generally less efficient than traditional silicon.

Nanostructured donors can be cast as uniform films that avoid the problems with defects. These would be subject to other issues inherent to quantum dots, notably resistivity issues and heat retention.

Multiple excitons

In 2004, Los Alamos National Laboratory reported spectroscopic evidence that several excitons could be efficiently generated upon absorption of a single, energetic photon in a quantum dot. Capturing them would catch more of the energy in sunlight. In this approach, known as “carrier multiplication” (CM) or “multiple exciton generation” (MEG), the quantum dot is tuned to release multiple electron-hole pairs at a lower energy instead of one pair at high energy. This increases efficiency through increased photocurrent. LANL’s dots were made from lead selenide.

In 2010, the University of Wyoming demonstrated similar performance using DCCS cells. Lead-sulfur (PbS) dots demonstrated two-electron ejection when the incoming photons had about three times the bandgap energy.

In 2005, NREL demonstrated MEG in quantum dots, producing three electrons per photon and a theoretical efficiency of 65%. In 2007, they achieved a similar result in silicon.

Non-oxidizing

In 2014 a University of Toronto group manufactured and demonstrated a type of CQD n-type cell using PbS with special treatment so that it doesn’t bind with oxygen. The cell achieved 8% efficiency, just shy of the current QD efficiency record. Such cells create the possibility of uncoated “spray-on” cells. However, these air-stable n-type CQD were actually fabricated in an oxygen-free environment.

Also in 2014, another research group at MIT demonstrated air-stable ZnO/PbS solar cells that were fabricated in air and achieved a certified 8.55% record efficiency (9.2% in lab) because they absorbed light well, while also transporting charge to collectors at the cell’s edge. These cells show unprecedented air-stability for quantum dot solar cells that the performance remained unchanged for more than 150 days of storage in air.

Source from Wikipedia