Grid-connected photovoltaic power system

A grid-connected photovoltaic power system, or grid-connected PV power system is an electricity generating solar PV power system that is connected to the utility grid. A grid-connected PV system consists of solar panels, one or several inverters, a power conditioning unit and grid connection equipment. They range from small residential and commercial rooftop systems to large utility-scale solar power stations. Unlike stand-alone power systems, a grid-connected system rarely includes an integrated battery solution, as they are still very expensive. When conditions are right, the grid-connected PV system supplies the excess power, beyond consumption by the connected load, to the utility grid.

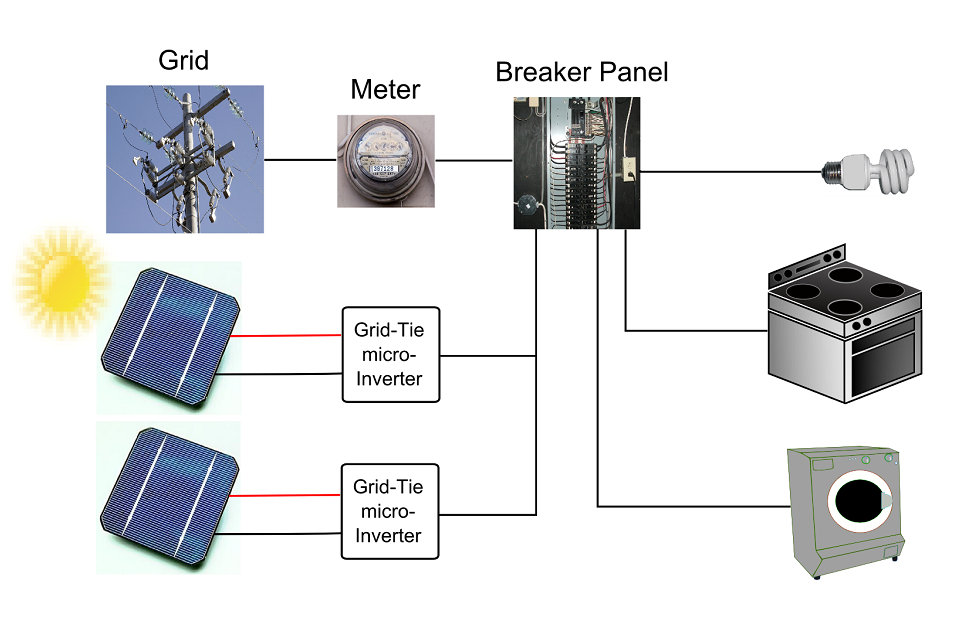

Components of a solar power system

A solar power system consists of solar panels, a mounting system, cabling, an inverter and a connection to the mains via a kilowatt hour meter.

Solar panels

The most visible part of a grid-connected solar power system is the solar panels. These catch the light and convert it into direct current.

Assembly

Solar power systems can be mounted in different ways. On sloping roofs, on flat roofs, on the ground, in the roof or with a sun-tracking system (and so-called tracker). You always have to look at the wind and snow load. If these are not properly calculated, a solar power system can fail or even collapse in strong winds or heavy snow. Most mounting systems are made of aluminum.

When mounted on a flat roof, a separate support structure is placed on which the panels are mounted, facing the sun. The most commonly used mounting form in the Netherlands and Belgium is mounting on a sloping roof. The solar power installation is installed directly on or in the roof. With a so-called ‘roof installation’, roof tiles are no longer installed, but the solar panels themselves are part of the roof. Such a construction has a higher aesthetic value, but drawbacks are that the mounting on an existing roof is more labor intensive, that there is less cooling air flow around the panels, so that the efficiency decreases, and that replacement is sometimes a problem if newer items have different dimensions..

Solar panels can also be mounted directly on the ground on an independent construction. Because of the unfavorable tax regime and the relatively high land price, this form is not often used in the Netherlands.

In a sun-tracking system, the solar panels follow the path of the sun. For this, the solar panels are mounted on a device that keeps them optimally directed towards the sun. Such a system has a higher yield but is more expensive to purchase and more susceptible to malfunctions.

Inverter

The inverter converts the DC voltage from the solar panels to alternating current of, for example, 230 or 110 volts that can be fed into the mains.

Operation

Residential, grid-connected rooftop systems which have a capacity more than 10 kilowatts can meet the load of most consumers. They can feed excess power to the grid where it is consumed by other users. The feedback is done through a meter to monitor power transferred. Photovoltaic wattage may be less than average consumption, in which case the consumer will continue to purchase grid energy, but a lesser amount than previously. If photovoltaic wattage substantially exceeds average consumption, the energy produced by the panels will be much in excess of the demand. In this case, the excess power can yield revenue by selling it to the grid. Depending on their agreement with their local grid energy company, the consumer only needs to pay the cost of electricity consumed less the value of electricity generated. This will be a negative number if more electricity is generated than consumed. Additionally, in some cases, cash incentives are paid from the grid operator to the consumer.

Connection of the photovoltaic power system can be done only through an interconnection agreement between the consumer and the utility company. The agreement details the various safety standards to be followed during the connection.

Features

Solar energy gathered by photovoltaic solar panels, intended for delivery to a power grid, must be conditioned, or processed for use, by a grid-connected inverter. Fundamentally, an inverter changes the DC input voltage from the PV to AC voltage for the grid. This inverter sits between the solar array and the grid, draws energy from each, and may be a large stand-alone unit or may be a collection of small inverters, each physically attached to individual solar panels. See AC Module. The inverter must monitor grid voltage, waveform, and frequency. One reason for monitoring is if the grid is dead or strays too far out of its nominal specifications, the inverter must not pass along any solar energy. An inverter connected to a malfunctioning power line will automatically disconnect in accordance with safety rules, for example UL1741, which vary by jurisdiction. Another reason for the inverter monitoring the grid is because for normal operation the inverter must synchronize with the grid waveform, and produce a voltage slightly higher than the grid itself, in order for energy to smoothly flow outward from the solar array.

Connection options

Production can be used in different ways:

Total self-consumption

Electrical production is consumed on site by the appliances in operation (self-consumption). If the instantaneous production exceeds the instantaneous consumption, the surplus is injected into the network without being counted;

Reversible Counting

Electrical production is consumed on site by the appliances in operation (self-consumption). If the instantaneous production exceeds the instantaneous consumption, the surplus is injected into the network and causes the electric meter to turn back (turning upside down, for the electromechanical meters). This solution is no longer used because it is incompatible with the new electronic meters;

Injection of the surplus

The electrical production consumed on site by the appliances in operation (self-consumption) is not counted by the production meter, but reduces the consumption count. Only the surplus of the production compared to the instantaneous consumption is sold;

Injection of the totality

All production is injected into the network and sold. A production-specific branch point is then created by the network manager. All consumption is also accounted for by the existing consumption meter, as in all buildings connected to the network.

Administrative Procedures

They are mandatory and must formalize the connection to the network of a photovoltaic production facility. The heaviness and the incessant change of these approaches are a major obstacle to the development of the national markets of certain countries (Italy, France).

Anti-islanding

Islanding is the condition in which a distributed generator continues to power a location even though power from the electric utility grid is no longer present. Islanding can be dangerous to utility workers, who may not realize that a circuit is still powered, even though there is no power from the electrical grid. For that reason, distributed generators must detect islanding and immediately stop producing power; this is referred to as anti-islanding.

In the case of a utility blackout in a grid-connected PV system, the solar panels will continue to deliver power as long as the sun is shining. In this case, the supply line becomes an “island” with power surrounded by a “sea” of unpowered lines. For this reason, solar inverters that are designed to supply power to the grid are generally required to have automatic anti-islanding circuitry in them. In intentional islanding, the generator disconnects from the grid, and forces the distributed generator to power the local circuit. This is often used as a power backup system for buildings that normally sell their power to the grid.

There are two types of anti-islanding control techniques:

Passive: The voltage and/or the frequency change during the grid failure is measured and a positive feedback loop is employed to push the voltage and/or the frequency further away from its nominal value. Frequency or voltage may not change if the load matches very well with the inverter output or the load has a very high quality factor (reactive to real power ratio). So there exists some Non Detection Zone (NDZ).

Active: This method employs injecting some error in frequency or voltage. When grid fails, the error accumulates and pushes the voltage and/or frequency beyond the acceptable range.

Technical aspects

The owner of the system, first the electricity produced beneficiary

Electricity always borrows preferentially the path of least electrical resistance. The owner of the system, whether electrical appliances are in operation at home, or his closest neighbors, receive a priori a significant (but not exclusive) share of the energy produced, without significant influence of the presence or absence of a electric meter on the way. Only the (modest) resistance of the counter intervenes. On the other hand, the choice of the injection option on the network does not intervene.

Installation and Connection Standards Miscellaneous

More or less stringent standards depending on the country exist. Most of the inverters sold in Europe are designed to comply with the German standards and connection requirements, due to the development of connected photovoltaic in Germany. These standards and requirements have often been adopted by the network operators of other European countries. For grid-connected photovoltaic systems, the inverters must comply with DIN VDE 0126 1.1 (Germany, France…) or be certified by an approved laboratory (United Kingdom, G77). As for photovoltaic modules, the standards to be respected in France are the following: IEC 61215 (crystalline type) and IEC 61646 (thin film type). For the dimensioning of the components, it is necessary to distinguish the continuous part CC (upstream of the inverter) and the AC alternative (downstream of the inverter). The texts in force are the guide of the UTE C15-712-1 for the part CC and the French standard NF C 15-100 for the CA 2 part.

Maintenance of a system connected to the network

The grid-connected photovoltaic system is the renewable energy system that is the easiest to operate because no preventive maintenance is necessary. The injection of the electricity produced on the network as well as the supply of the consumption of the site is done automatically. With the exception of a smoky or dusty industrial site, the cleaning of the sensors is done naturally by wind and rain. Simple monitoring can detect possible system failures. However, it is necessary to provide for the replacement of the inverter which has, on average, a service life of 8 to 12 years.

Advantages

Systems such as Net Metering and Feed-in Tariff which are offered by some system operators, can offset a customers electricity usage costs. In some locations though, grid technologies cannot cope with distributed generation feeding into the grid, so the export of surplus electricity is not possible and that surplus is earthed.

Grid-connected PV systems are comparatively easier to install as they do not require a battery system.

Grid interconnection of photovoltaic (PV) power generation systems has the advantage of effective utilization of generated power because there are no storage losses involved.

A photovoltaic power system is carbon negative over its lifespan, as any energy produced over and above that to build the panel initially offsets the need for burning fossil fuels. Even though the sun doesn’t always shine, any installation gives a reasonably predictable average reduction in carbon consumption.

Disadvantages

Grid-connected PV can cause issues with voltage regulation. The traditional grid operates under the assumption of one-way, or radial, flow. But electricity injected into the grid increases voltage, and can drive levels outside the acceptable bandwidth of ±5%.

Grid-connected PV can compromise power quality. PV’s intermittent nature means rapid changes in voltage. This not only wears out voltage regulators due to frequent adjusting, but also can result in voltage flicker.

Connecting to the grid poses many protection-related challenges. In addition to islanding, as mentioned above, too high levels of grid-connected PV result in problems like relay desensitization, nuisance tripping, interference with automatic reclosers, and ferroresonance.

Economic aspects

Cost of systems

The overall price of a photovoltaic system depends on:

of a possible preliminary study (atypical legal assembly, medium or large systems)

the type of equipment and installation conditions;

network connection;

borrowing interest where applicable.

The price of the equipment depends mainly on the size of the system and how it is integrated into the building.

Material price and installation included:

| Power | Floor or roof installation | Roof integration, simple | glass integration, PV tiles … |

|---|---|---|---|

| 1 to 3 kWp | 5 to 7 € / Wc | 5 to 7 € / Wc | > 7 € / Wc |

| 3 to 10 kWp | 3,5 to 5 € / Wc | 3,5 to 5 € / Wc | > 5 € / Wc |

| from 10 kWp to 36 kWp | 3 to 5 € / Wc | 3,5 to 5 € / Wc | <10 € / Wc |

| from 36 kWp to several MW | 2 to 4 € / Wc | 3 to 4.5 € / Wc | <7 € / Wc |

payback time

The total costs of solar panels consist of the purchase, depreciation, interest on loans, placement, maintenance, insurance and possibly the license and the subsidy. The payback time depends on the location of the solar panels, the method of assembly and the development of the electricity price. The payback period for photovoltaic solar panels is gradually decreasing. When mounted directly to the south on a tile roof, this year 2015 will be around 7 years at the same electricity price.

Permit

It is sometimes necessary to apply for a permit for the installation of solar panels. This is the case, for example, with protected village or town views and / or monuments.

Energy price

On average, a watt peak (Wp) of a crystalline solar panel costs about 1 euro (excluding assembly). 100 Wp produces approximately 70 to 90 kWh per year of energy in the Netherlands, depending on the location, the angle of the roof, the amount of shade and the type of solar panel. The calculation is based on the fact that the solar panels supply energy that they do not have to buy from the electricity company. Electricity company costs about 0.20 to 0.23 euros per kWh (in 2013). If on balance you generate more electricity than you need, this can be sold to the electricity company for the feed-in fee of about 0.05 to 0.09 euros per kWh, which is much less lucrative.

Tax incentives

Many European governments have chosen to encourage solar energy for tax purposes.

VAT on Solar panels

Because of the Fuchs judgment, it has been possible since 20 June 2013 to request the VAT paid on solar panels from the tax authorities.

Energy balance

The production of solar panels also requires energy. The measure is expressed in the time in which this energy is generated. This is called the energy balance and in Belgium and the Netherlands it is between 1 and 2 years.

Remuneration for the production of electricity injected into the networks

Different types of remuneration exist according to the political choices of the different countries.

Quotas

“Green certificates” and “guarantees of origin”. Kilowatt-hours produced are paid for by selling “green certificates” or “guarantees of origin” to organizations that need them.

Purchase price

Feed in Tariff, or FIT, kilowatt-hours are paid for by a purchase tariff, the level of which is set by the State or the buyer, according to the legislation of the country or the State. In France, the decree of March, 2011provides for a quarterly review of the purchase prices for photovoltaic energy. These tariffs are made public by the Energy Regulatory Commission (CRE) which is charged by the government with the deliberation of coefficients S and V which determine the feed-in tariff. Since March 2011, the purchase price may change each quarter depending in particular on the number of requests for connection to the network. Since these rates are higher than market prices, the operators subject to the purchase obligation are compensated for the additional cost by a surcharge applied to all kWh billed: the CSPE.

Profitability of the systems

These systems are not in themselves “profitable” at the level of the community as a whole if only the financial costs are taken into account, since the electricity produced is more expensive than that produced by other electricity generation systems (including renewable energy: wind, solar thermodynamics, etc.), because of the high costs of investment due to the still high price of photovoltaic modules, but the current support policy allows to lower costs so that this clean energy becomes profitable (what will be facilitated by the inevitable increase in the cost of fossil fuels).

However in 2010, thanks to direct or indirect subsidies, a facility can be very profitable for its owner. A facility installed in 2008 and 2009 in the south of France, generated returns of more than 12%; for example, a plant in the south of France costing €7 per watt-peak at the laying produced in the year 1.4 kWh, paid € 0.601 76 / kWh (€0.58 / kWh in 2010), almost the double of the German purchase price, without risks (the sunshine varies little, the material is very reliable, and the price of purchase is guaranteed).

Perpignan is, in 2011, the city that hosts the largest photovoltaic installation in the world integrated to buildings (excluding photovoltaic solar power plants); the Saint-Charles International site includes 97,000 photovoltaic tiles on 68,000 m2 of roofing. It produces more than 9800 MWh per year (enough to power a city of more than 8000 inhabitants in electricity).

Source from Wikipedia