Artificial muscle is a generic term used for actuators, materials or devices that mimic natural muscle and can reversibly contract, expand, or rotate within one component due to an external stimulus (such as voltage, current, pressure or temperature). The three basic actuation responses – contraction, expansion, and rotation – can be combined together within a single component to produce other types of motions (e.g. bending, by contracting one side of the material while expanding the other side). Conventional motors and pneumatic linear or rotary actuators do not qualify as artificial muscles, because there is more than one component involved in the actuation.

Due to their high flexibility, versatility and power-to-weight ratio compared with traditional rigid actuators, artificial muscles have the potential to be a highly disruptive emerging technology. Though currently in limited use, the technology may have wide future applications in industry, medicine, robotics and many other fields.

Overview

These include not only those imitating the actual animal muscle structure by biotechnology but also actuators that generate power by changing the state by consuming electrical, magnetic or chemical energy.

There are various types of artificial muscles such as piezoelectric type, shape memory alloy, electrostatic type, pneumatic type and the like, but recently, those using polymer such as synthetic resin attract attention. It is said that it is soft actuator, because the material to be used is soft, the motion is flexible, and it also supports external forces.

In the mechanical device, there is a tendency to output a predetermined momentum with respect to the input energy, but if some restriction physically exists, the barrier or the mechanical device itself will be damaged. In the artificial muscle, although the exercising is performed with a certain width with respect to the input energy, at the same time when a force is input from the outside or a predetermined momentum can not be exhibited, this power unit itself generates excessive momentum in the form of distortion It is thought to have the function of preventing absorption, destruction of the equipment and damage of the object.

These “soft” power sources can temporarily place energy that mechanical torque is excessively consumed due to friction inside and outside the mechanism, in the form of elasticity, so we developed a more efficient device In addition to the fact that machine elements and structures do not generate power, but the material itself is a power source, it can be said that it is useful for miniaturization of the device.

However, as of 2010, as for materials used as artificial muscles, many piezoelectric and polymeric materials are in the development and research stages, many can not be mass-produced at low cost • It is not possible to convert input energy into momentum Applications to products sold as generally usable products are limited, due to low conversion efficiency and problems of pressure resistance / durability, it seems that it takes time to disseminate. The function as actuator can be achieved by applying the principle of commercially available compact motor, linear motor (including voice coil motor) etc., this can be used as inexpensive existing products available as modules Products that use these are mainstream because they can.

Comparison with natural muscles

While there is no general theory that allows for actuators to be compared, there are “power criteria” for artificial muscle technologies that allow for specification of new actuator technologies in comparison with natural muscular properties. In summary, the criteria include stress, strain, strain rate, cycle life, and elastic modulus. Some authors have considered other criteria (Huber et al., 1997), such as actuator density and strain resolution. As of 2014, the most powerful artificial muscle fibers in existence can offer a hundredfold increase in power over equivalent lengths of natural muscle fibers.

Researchers measure the speed, energy density, power, and efficiency of artificial muscles; no one type of artificial muscle is the best in all areas.

Types

Artificial muscles can be divided into three major groups based on their actuation mechanism.

Electric field actuation

Electroactive polymers (EAPs) are polymers that can be actuated through the application of electric fields. Currently, the most prominent EAPs include piezoelectric polymers, dielectric actuators (DEAs), electrostrictive graft elastomers, liquid crystal elastomers (LCE) and ferroelectric polymers. While these EAPs can be made to bend, their low capacities for torque motion currently limit their usefulness as artificial muscles. Moreover, without an accepted standard material for creating EAP devices, commercialization has remained impractical. However, significant progress has been made in EAP technology since the 1990s.

Ion-based actuation

Ionic EAPs are polymers that can be actuated through the diffusion of ions in an electrolyte solution (in addition to the application of electric fields). Current examples of ionic electroactive polymers include polyelectrode gels, ionomeric polymer metallic composites (IPMC), conductive polymers and electrorheological fluids (ERF). In 2011, it was demonstrated that twisted carbon nanotubes could also be actuated by applying an electric field.

Electric power actuation

Twisted and coiled polymer (TCP) muscles also known as supercoiled polymer (SCP) are coiled polymer that can be actuated by electric power. A TCP muscle look like a helical spring. TCP muscles are usually made from silver coated Nylon. TCP muscle can also made from other electrical conductance coat such as gold. TCP muscles should be under a load to keep the muscle extended. The electrical energy transforms to thermal energy due to electrical resistance, which also known as Joule heating, Ohmic heating, and resistive heating. As the temperature of the TCP muscle increases by Joule heating, the polymer contracts and it causes the muscle contraction..

Pneumatic actuation

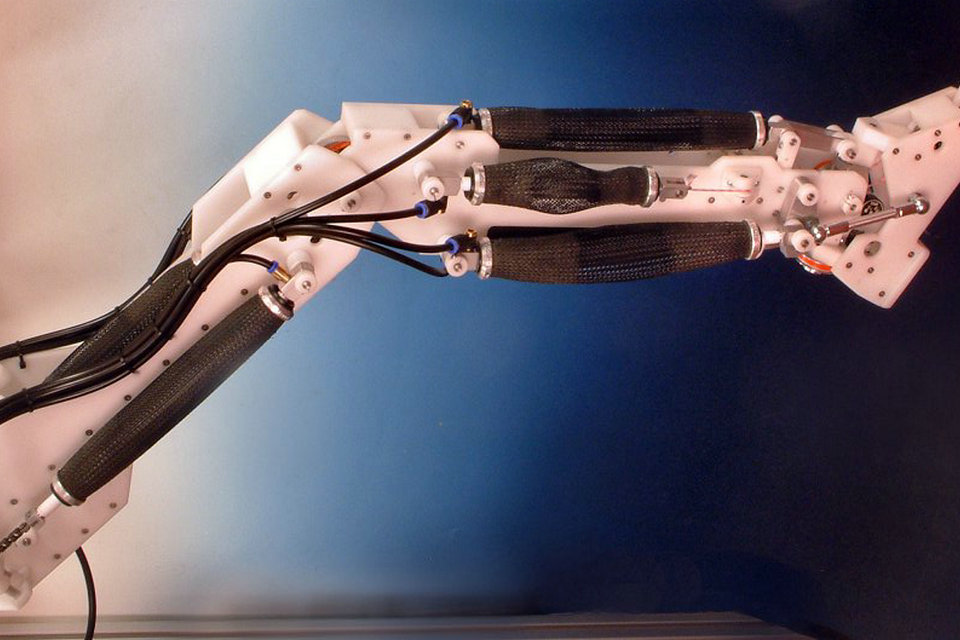

Pneumatic artificial muscles (PAMs) operate by filling a pneumatic bladder with pressurized air. Upon applying gas pressure to the bladder, isotropic volume expansion occurs, but is confined by braided wires that encircle the bladder, translating the volume expansion to a linear contraction along the axis of the actuator. PAMs can be classified by their operation and design; namely, PAMs feature pneumatic or hydraulic operation, overpressure or underpressure operation, braided/netted or embedded membranes and stretching membranes or rearranging membranes. Among the most commonly used PAMs today is a cylindrically braided muscle known as the McKibben Muscle, which was first developed by J. L. McKibben in the 1950s.

Thermal actuation

Fishing line

Artificial muscles constructed from ordinary fishing line and sewing thread can lift 100 times more weight and generate 100 times more power than a human muscle of the same length and weight.

Artificial muscles based on fishing line already cost orders of magnitude less (per pound) than shape-memory alloy or carbon nanotube yarn; but currently have relatively poor efficiency.

Individual macromolecules are aligned with the fiber in commercially available polymer fibers. By winding them into coils, researchers make artificial muscles that contract at speeds similar to human muscles.

A (untwisted) polymer fiber, such as polyethelene fishing line or nylon sewing thread, unlike most materials, shortens when heated—up to about 4% for a 250 K increase in temperature. By twisting the fiber and winding the twisted fiber into a coil, heating causes the coil to tighten up and shorten by up to 49%. Researchers found another way to wind the coil such that heating causes the coil to lengthen by 69%.

One application of thermally-activated artificial muscles is to automatically open and close windows, responding to temperature without using any power.

Tiny artificial muscles composed of twisted carbon nanotubes filled with paraffin are 200 times stronger than human muscle.

Shape-memory alloys

Shape-memory alloys (SMAs), liquid crystalline elastomers, and metallic alloys that can be deformed and then returned to their original shape when exposed to heat, can function as artificial muscles. Thermal actuator-based artificial muscles offer heat resistance, impact resistance, low density, high fatigue strength, and large force generation during shape changes. In 2012, a new class of electric field-activated, electrolyte-free artificial muscles called “twisted yarn actuators” were demonstrated, based on the thermal expansion of a secondary material within the muscle’s conductive twisted structure. It has also been demonstrated that a coiled vanadium dioxide ribbon can twist and untwist at a peak torsional speed of 200,000 rpm.

Artificial muscle using polymer

Electric Responsive Polymer (English version) (Electroactive Polymers: EAP)

Ionic Conductive Polymer Film (ICPF: Ionic Conducting Polymer Film)

In 1991, it was invented by Keisuke Oguchi (Osaka Industrial Technology Research Institute, National Institute of Advanced Industrial Science and Technology, former AIST) and others.

Noble metal (gold, platinum) electrolessly plated on both sides of perfluoro sulfonic acid (PFS) film, and bending at high speed when voltage is applied to both side electrodes.

Artificial muscle using pneumatic pressure

Pneumatic artificial muscles (PAMs)

McKibben type (artificial muscle)

In 1961, it was developed by Joseph McKibben.

It is shaped like a rubber tube covered with nylon fiber and contracted by applying compressed air inside.

Origami Robot – developed by MIT Computer Science and Artificial Intelligence Laboratory (CSAIL). Artificial muscle combining origami structure and vacuum pack. By pulling out the air inside the vacuum pack, the inner folding paper also deforms interlocking and becomes a skeleton.

Artificial muscles using electricity and magnetism

Using electrorheological fluid

Using magnetic viscous fluid (magnetorheological fluid)

Using electrostatic attraction

An actuator utilizing electrostatic force, such as “high power electrostatic motor” under research and development by Higuchi • Yamamoto laboratory of the University of Tokyo, can also be applied as artificial muscle. Videos of Electroactive Polymers in Action

CNT muscle fiber

An artificial muscle structured to contract by adding a voltage of about 5 kV to a processed carbon nanotube was developed at the Nanotechnology Research Institute of the University of Texas at Dallas. The artificial muscle has only a slightly heavier density than air, has a fast rate of contraction and is 30 times more power per area than biological muscle. (Note that it is not particularly strong compared to other artificial muscles that thirty times the body muscle.

Control systems

The three types of artificial muscles have different constraints that affect the type of control system they require for actuation. It is important to note, however, that control systems are often designed to meet the specifications of a given experiment, with some experiments calling for the combined use of a variety of different actuators or a hybrid control schema. As such, the following examples should not be treated as an exhaustive list of the variety of control systems that may be employed to actuate a given artificial muscle.

Voltage control

The twisted and coiled polymer (TCP) muscles can be modeled by first-order linear time-invariant state spaces when input is electrical voltage, with accuracy more than 85%. Therefore, A TCP muscles can be easily controlled by a digital PID controller. A fuzzy controller can be used to speed up the PID controller.

EAP control

EAPs offer lower weight, faster response, higher power density and quieter operation when compared to traditional actuators. Both electric and ionic EAPs are primarily actuated using feedback control loops, better known as closed-loop control systems.

Pneumatic control

Currently there are two types of pneumatic artificial muscles (PAMs). The first type has a single bladder surrounded by a braided sleeve and the second type has a double bladder.

Single bladder surrounded by a braided sleeve

Pneumatic artificial muscles, while lightweight and inexpensive, pose a particularly difficult control problem as they are both highly nonlinear and have properties, such as temperature, that fluctuate significantly over time. PAMs generally consist of rubber and plastic components. As these parts come into contact with each other during actuation, the PAM’s temperature increases, ultimately leading to permanent changes in the structure of the artificial muscle over time. This problem has led to a variety of experimental approaches. In summary (provided by Ahn et al.), viable experimental control systems include PID control, adaptive control (Lilly, 2003), nonlinear optimal predictive control (Reynolds et al., 2003), variable structure control (Repperger et al., 1998; Medrano-Cerda et al.,1995), gain scheduling (Repperger et al.,1999), and various soft computing approaches including neural network Kohonen training algorithm control (Hesselroth et al.,1994), neural network/nonlinear PID control (Ahn and Thanh, 2005), and neuro-fuzzy/genetic control (Chan et al., 2003; Lilly et al., 2003).

Control problems regarding highly nonlinear systems have generally been addressed through a trial-and-error approach through which “fuzzy models” (Chan et al., 2003) of the system’s behavioral capacities could be teased out (from the experimental results of the specific system being tested) by a knowledgeable human expert. However, some research has employed “real data” (Nelles O., 2000) to train up the accuracy of a given fuzzy model while simultaneously avoiding the mathematical complexities of previous models. Ahn et al.’s experiment is simply one example of recent experiments that use modified genetic algorithms (MGAs) to train up fuzzy models using experimental input-output data from a PAM robot arm.

Double bladder

This actuator consists of an external membrane with an internal flexible membrane dividing the interior of the muscle into two portions. A tendon is secured to the membrane, and exits the muscle through a sleeve so that the tendon can contract into the muscle. A tube allows air into the internal bladder, which then rolls out into the external bladder. A key advantage of this type of pneumatic muscle is that there is no potentially frictive movement of the bladder against an outer sleeve.

Thermal control

SMA artificial muscles, while lightweight and useful in applications that require large force and displacement, also present specific control challenges; namely, SMA artificial muscles are limited by their hysteretic input-output relationships and bandwidth limitations. As Wen et al. discuss, the SMA phase transformation phenomenon is “hysteretic” in that the resulting output SMA strand is dependent on the history of its heat input. As for bandwidth limitations, the dynamic response of an SMA actuator during hysteretic phase transformations is very slow due to the amount of time required for the heat to transfer to the SMA artificial muscle. Very little research has been conducted regarding SMA control due to assumptions that regard SMA applications as static devices; nevertheless, a variety of control approaches have been tested to address the control problem of hysteretic nonlinearity.

Generally, this problem has required the application of either open-loop compensation or closed-loop feedback control. Regarding open-loop control, the Preisach model has often been used for its simple structure and ability for easy simulation and control (Hughes and Wen, 1995). As for closed-loop control, a passivity-based approach analyzing SMA closed loop stability has been used (Madill and Wen, 1994). Wen et al.’s study provides another example of closed-loop feedback control, demonstrating the stability of closed-loop control in SMA applications through applying a combination of force feedback control and position control on a flexible aluminum beam actuated by an SMA made from Nitinol.

Applications

Artificial muscle technologies have wide potential applications in biomimetic machines, including robots, industrial actuators and powered exoskeletons. EAP-based artificial muscles offer a combination of light weight, low power requirements, resilience and agility for locomotion and manipulation. Future EAP devices will have applications in aerospace, automotive industry, medicine, robotics, articulation mechanisms, entertainment, animation, toys, clothing, haptic and tactile interfaces, noise control, transducers, power generators, and smart structures.

Pneumatic artificial muscles also offer greater flexibility, controllability and lightness compared to conventional pneumatic cylinders. Most PAM applications involve the utilization of McKibben-like muscles. Thermal actuators such as SMAs have various military, medical, safety, and robotic applications, and could furthermore be used to generate energy through mechanical shape changes.

Source from Wikipedia