Compressed-air vehicle

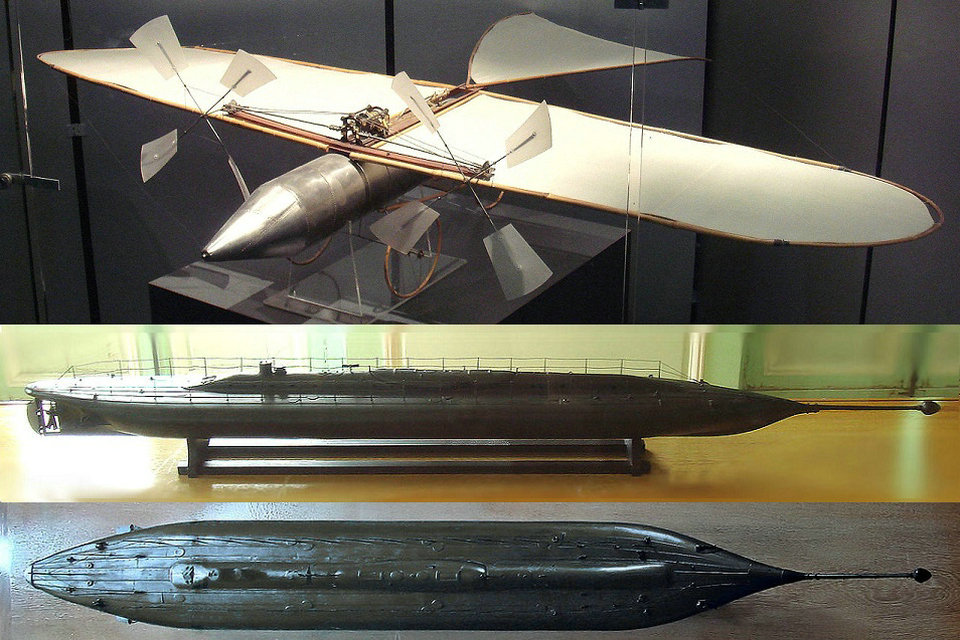

A compressed-air vehicle (CAV) is a transport mechanism fueled by tanks of pressurized atmospheric gas and propelled by the release and expansion of the gas within a Pneumatic motor. CAV’s have found application in torpedoes, locomotives used in digging tunnels, and early prototype submarines. Potential environmental advantages have generated public interest in CAV’s as passenger cars, but they have not been competitive due to the low energy density of compressed air and inefficiency of the compression / expansion process.

Compressed-air propulsion may also be incorporated in hybrid systems, such as with battery electric propulsion. This kind of system is called a hybrid-pneumatic electric propulsion. Additionally, regenerative braking can also be used in conjunction with this system.

History

The use of compressed air as a driving force of a vehicle dates back to the development of railways and mechanical traction tramways where, in some situations, such as mining and urban networks, it was necessary to avoid the risks of fire and the pollution inherent to the ordinary steam locomotive.

The first systems of Tomlinson (1820 ) in the United States or Andraud (1830 ) in France were failures because the compressed air circulated in a pipe along the track and the locomotive had to be equipped to take it continuously. (by a device similar to the catapults of aircraft carriers) which caused leaks and poor performance.

A new system designed by Antoine Andraud and Cyprien Tessie du Motay in Paris in 1840, where the locomotive was equipped with a tank that was filled at certain points of the network, proved the feasibility of the system.

The first practical applications of compressed air rail vehicles date back to the breakthrough of railway tunnels (1872 ), particularly that of the Gotthard in Switzerland, and some tramway experiments. But the cooling of the engine cylinder by the expansion of the compressed air transformed the humidity of the engine air into ice crystals which caused blockages.

It was the engineer Louis Mekarski who perfected the system, combining compressed air and superheated water under pressure, and made it fully operational in order to equip trams networks. It was first tested in the Parisian trams from 1876 to 1879 on the network Tramways North.

Then it was used on several lines of the Île-de-France network: Nogentan Railways, Sèvres Tramway to Versailles, Tramway Company of Saint-Maur-des-Fossés and on the Paris network of the Compagnie Générale des Omnibus from 1894 to 1914.

From 1879, the entire network of Nantes tramways was gradually equipped with more than 90 compressed air vehicles which gave satisfaction until 1917. From 1890, other cities equipped themselves with Mekarski trams like Berne (1890), Vichy (1895), Aix-les-Bains (1896), Saint-Quentin (1899) and La Rochelle (1901). Mekarski locomotives were also in service on the Paris part of the Arpajonnais for the “silent” service of the Halles de Paris from 1895until 1901.

One of New York’s light rail projects was to use compressed air and overheated water locomotives. The engine ran on regenerative braking, recharging the compressed air tank and warming the water tank.

From 1896, the HK Porter Company of Pittsburgh put on the market compressed air locomotive invented by Charles B. Hodges. The double and triple expansion engine (high and low pressure cylinders) was supplemented by an atmospheric heat exchanger. Compressed air cooled by the first expansion was warmed by ambient air, making the superheated water device unnecessary and greatly improving overall efficiency. Thousands of Porter locomotives powered coal mines in the eastern United States until the 1930s. Other manufacturers around the world have produced similar machines for mines and factories in industries that do not tolerate smoke or dust. The range increased with the possibility of building air reservoirs with very high pressure (up to 250 bars). These machines served until the 1950s, before being overtaken by the development of low-emission gas engines and improved electric accumulators.

The implementation for the automobile has also been the subject of some achievements. Less polluting than the electric vehicle (which pollutes by the components of its batteries), but also suffering from a limited autonomy, the concept seems forgotten of the “ecological” world and does not benefit for the moment of any big industrialist for its promotion and its development. Several companies, however, are working on the application of the compressed air motor for the automobile.

On May 7, 2012, the Indian company Tata Motors, which builds very compact low-cost vehicles, announced that it had successfully passed in cooperation with the MDI company, tests of use on prototypes and started a phase of setting up the process. of manufacture of this vehicle.

Theory

According to Boyle’s law,

For a fixed mass of ideal gases at a fixed temperature, the magnitude of the pressure by the magnitude of the volume results in a constant.

Robert Boyle and Edme Mariotte

Therefore, under an identical temperature:

the pressure multiplied by the volume of the gas contained in a tank corresponds to a constant;

the variation of the gas pressure is inversely proportional to its volume.

If either of the two, either the pressure or the volume is altered, the factor T can therefore be modified. Which brings us to the concepts of thermodynamics, the adiabatic expansion of compressed air.

The faster and more brutal the change in the product of pressure and volume, the gas manages to satisfy this constant in less time and reflects part of this conversion in temperature.

This is the reason why the methods of using compressed air in a system explain why with compressed air motors with two main tendencies, conceptually different:

Thermodynamic exploitation

At the time of rapid expansion of a large amount of compressed air, corresponding to a significant decrease in pressure, it is physically impossible for the gas to recover its initial volume; the temperature variation that follows produces a significant cooling, while the expansion of the useful volume can be limited to approximately 40% of the theoretical volume. Conversely, with compression, volume reduction generally involves a rise in temperature, resulting once again in a total volume of compressed air lower than its theoretical value.

The technologies exploited by MDI, Energine and Quasiturbine require relatively important flows when exploiting to animate the engines, but must necessarily be constrained by thermodynamic limitations.

Dynamics of exploitation

To produce a mechanical thrust while avoiding this obstacle, or, at least, while reducing its effects, so it is necessary to comply with certain rules: to allow expansion as slowly as possible, that is, while working with Low currents (but this, of course, means a negative counterpart as far as the limitation of the motor power is concerned), to regulate the sudden variations of the pressure when it is too important (by the use of pressure reducers and other decompression intermediates enabled), to maintain, as well as the possible constant temperature of the gas, if not even to increase the performance of the compression / expansion of a cooling / heating of the utility of the air.

Technology

The compressed air motor and the compressed air tanks are special cases of pneumatic systems, which use the principles of thermodynamics of compressible gases presented in the corresponding articles.

Pneumatic, electrical and thermal comparison

Compared to the electric motor or the internal combustion engine, the pneumatic motor has certain advantages but also weaknesses of importance for its adaptation to the automobile transport:

Regarding the accumulation of energy

the cost of manufacturing the compressed air reservoir is lower than that of an electric accumulator, but higher than that of a fuel tank;

a composite air tank is much less heavy than an electric accumulator, but more than a fuel tank;

the manufacture of an air tank can be expensive in energy (carbon fiber ) but does not include highly polluting metals (unlike many types of electric accumulators);

the compressed air tank wears little and can sustain more than 10,000 cycles of charging and discharging, giving it a virtually unlimited life;

recycling of the compressed air tank is easier than that of an electric accumulator;

for mobile use, the mass of air carried decreases during the use of the vehicle, just as for fuel, unlike the weight of the electric accumulator;

however, the energy content of the compressed air is low; for example, a volume of 300 liters at 300 bar can only provide a theoretical maximum of 14.3 kWh and, in practice, this figure is reduced to about 7 kWh for adiabatic expansion, which is close to the behavior real pneumatic motors;

the charging and discharging of an electric accumulator can be done with an energy efficiency approaching 90%, associated with an efficiency of an electric motor between 90 and 96%, which gives an overall efficiency of about 70%. at 75%;

the pressure drops when the air tank empties, resulting in either a drop in available power, or a decrease in efficiency if a regulator is used to regulate the pressure;

the humidity of the compressed air must be completely removed to prevent ice formation during expansion in the engine: either the water is removed before compression, or the compressed air is heated during expansion, creating significant additional energy losses;

the electric charging is silent while the air compression is not.

About the engine

the pneumatic motor can operate at low speed (100 to 2000 revolutions per minute according to the cubic capacity) ;

it offers a large and almost constant torque over the rev range of the engine ;

it could provide cold for the vehicle; on the other hand, in the absence of heat losses of an internal combustion engine, it is necessary to provide additional heat to heat the vehicle;

a conventional thermal engine of the same power (about 7 kW ) that a compressed air motor is of comparable or even smaller size and weight (see propulsion engines for model aircraft, etc.).

Regarding commercial viability

compressed air vehicles have failed to reach commercialization despite several decades of development; on the other hand, many manufacturers have put on the market different models of electric vehicles whose global sales show a steady growth;

the performances announced by the creators of compressed air vehicles have never been verified independently and can therefore be questioned.

Compared to internal combustion engines, both pneumatic and electrical systems have the disadvantage of low autonomy was acceptable for vehicles like the tram of the early 20th century, with their frequent stops and fixed routes allowing quick recharging air but is less compatible with the current use of a particular vehicle. However, the use of state-of-the-art techniques (carbon fiber air tanks) could help reduce this disadvantage by lightening vehicles (see the chapter on “autonomy” and methods for estimating energy in the air). article pneumatic energy ).

Tanks

The tanks must be designed to safety standards appropriate for a pressure vessel, such as ISO 11439.

The storage tank may be made of metal or composite materials. The fiber materials are considerably lighter than metals but generally more expensive. Metal tanks can withstand a large number of pressure cycles, but must be checked for corrosion periodically.

One company stores air in tanks at 4,500 pounds per square inch (about 30 MPa) and hold nearly 3,200 cubic feet (around 90 cubic metres) of air.

The tanks may be refilled at a service station equipped with heat exchangers, or in a few hours at home or in parking lots, plugging the car into the electrical grid via an on-board compressor. The cost of driving such a car is typically projected to be around €0.75 per 100 km, with a complete refill at the “tank-station” at about US$3.

Compressed air

Compressed air has a low energy density. In 300 bar containers, about 0.1 MJ/L and 0.1 MJ/kg is achievable, comparable to the values of electrochemical lead-acid batteries. While batteries can somewhat maintain their voltage throughout their discharge and chemical fuel tanks provide the same power densities from the first to the last litre, the pressure of compressed air tanks falls as air is drawn off. A consumer-automobile of conventional size and shape typically consumes 0.3–0.5 kWh (1.1–1.8 MJ) at the drive shaft per mile of use, though unconventional sizes may perform with significantly less.

Emission output

Like other non-combustion energy storage technologies, an air vehicle displaces the emission source from the vehicle’s tail pipe to the central electrical generating plant. Where low emissions sources are available, net production of pollutants can be reduced. Emission control measures at a central generating plant may be more effective and less costly than treating the emissions of widely dispersed vehicles.

Since the compressed air is filtered to protect the compressor machinery, the air discharged has less suspended dust in it, though there may be carry-over of lubricants used in the engine. The car works when gas expands.

Advantages

Compressed-air vehicles are comparable in many ways to electric vehicles, but use compressed air to store the energy instead of batteries. Their potential advantages over other vehicles include:

Much like electrical vehicles, air powered vehicles would ultimately be powered through the electrical grid. Which makes it easier to focus on reducing pollution from one source, as opposed to the millions of vehicles on the road.

Transportation of the fuel would not be required due to drawing power off the electrical grid. This presents significant cost benefits. Pollution created during fuel transportation would be eliminated.

Compressed-air technology reduces the cost of vehicle production by about 20%, because there is no need to build a cooling system, fuel tank, Ignition Systems or silencers.

The engine can be massively reduced in size.

The engine runs on cold or warm air, so can be made of lower strength light weight material such as aluminium, plastic, low friction teflon or a combination.

Low manufacture and maintenance costs as well as easy maintenance.

Compressed-air tanks can be disposed of or recycled with less pollution than batteries.

Compressed-air vehicles are unconstrained by the degradation problems associated with current battery systems.

The air tank may be refilled more often and in less time than batteries can be recharged, with re-filling rates comparable to liquid fuels.

Lighter vehicles cause less damage to roads, resulting in lower maintenance cost.

The price of filling air powered vehicles is significantly cheaper than petrol, diesel or biofuel. If electricity is cheap, then compressing air will also be relatively cheap.

Disadvantages

The principal disadvantage is the indirect use of energy. Energy is used to compress air, which – in turn – provides the energy to run the motor. Any conversion of energy between forms results in loss. For conventional combustion motor cars, the energy is lost when oil is converted to usable fuel – including drilling, refinement, labor, storage, eventually transportation to the end-user. For compressed-air cars, energy is lost when electrical energy is converted to compressed air, and when fuel, whether coal, natural gas or nuclear, is burned to drive the electrical generators.

When air expands, as it would in the engine, it cools dramatically (Charles’s law) and must be heated to ambient temperature using a heat exchanger similar to the Intercooler used for internal combustion engines. The heating is necessary in order to obtain a significant fraction of the theoretical energy output. The heat exchanger can be problematic. While it performs a similar task to the Intercooler, the temperature difference between the incoming air and the working gas is smaller. In heating the stored air, the device gets very cold and may ice up in cool, moist climates.

Refueling the compressed-air container using a home or low-end conventional air compressor may take as long as 4 hours, while the specialized equipment at service stations may fill the tanks in only 3 minutes.

Tanks get very hot when filled rapidly. SCUBA tanks are sometimes immersed in water to cool them down when they are being filled. That would not be possible with tanks in a car and thus it would either take a long time to fill the tanks, or they would have to take less than a full charge, since heat drives up the pressure. However, if well insulated, such as Dewar (vacuum) flask design, the heat would not have to be lost but put to use when the car was running.

Early tests have demonstrated the limited storage capacity of the tanks; the only published test of a vehicle running on compressed air alone was limited to a range of 7.22 km (4 mi).

A 2005 study demonstrated that cars running on lithium-ion batteries out-perform both compressed-air and fuel cell vehicles more than threefold at same speeds. MDI has recently claimed that an air car will be able to travel 140 km (87 mi) in urban driving, and have a range of 80 km (50 mi) with a top speed of 110 km/h (68 mph) on highways, when operating on compressed air alone.

Possible improvements

Compressed-air vehicles operate according to a thermodynamic process because air cools down when expanding and heats up when being compressed. Since it is not practical to use a theoretically ideal process, losses occur and improvements may involve reducing these, e.g., by using large heat exchangers in order to use heat from the ambient air and at the same time provide air cooling in the passenger compartment. At the other end, the heat produced during compression can be stored in water systems, physical or chemical systems and reused later.

It may be possible to store compressed air at lower pressure using an absorption material within the tank. Absorption materials like Activated carbon, or a metal organic framework is used for storing compressed natural gas at 500 psi instead of 4500 psi, which amounts to a large energy saving.

Vehicles

Production cars

Several companies are investigating and producing prototypes including hybrid compressed-air/gasoline-combustion vehicles. As of August 2017, none of the developers have yet gone into production, although Tata has indicated they will begin selling vehicles from 2020 and MDI’s US distributor Zero Pollution Motors says production of the AIRPod will commence in Europe in 2018.

Experimental cars and bikes

In 2008, a compressed air and natural gas powered vehicle designed by engineering students at Deakin University in Australia was joint winner of the Ford Motor Company T2 competition to produce a car with a 200 km range and a cost of less than $7,000.

Australian company Engineair has produced a number of vehicle types – moped, small car, small carrier, go-cart – around the rotary compressed air engine created by Angelo Di Pietro. The company is seeking partners to utilise its engine.

A compressed-air powered motorcycle, called the Green Speed Air Powered Motorcycle was made by Edwin Yi Yuan, based on the Suzuki GP100 and using the Angelo Di Pietro compressed-air engine.

Three mechanical engineering students from San Jose State University; Daniel Mekis, Dennis Schaaf and Andrew Merovich, designed and built a bike that runs on compressed air. The total cost of the prototype was under $1000 and was sponsored by Sunshops (on the Boardwalk in Santa Cruz, California) and NO DIG NO RIDE (from Aptos, California.). The top speed of the maiden voyage in May 2009 was 23 mph While their design was simple, these three pioneers of compressed air powered vehicles helped pave the way for French automaker Peugeot Citreon to invent a brand new air-powered hybrid. The ‘Hybrid Air’ system uses compressed air to move the car’s wheels when driving under 43 mph. Peugeot says the new hybrid system should get up to 141 miles per gallon of gas. Models should roll out as early as 2016. The head of the project left Peugeot in 2014 and in 2015 the company said it had been unable to find a partner to share the development costs, effectively ending the project..

“Ku:Rin” named air-compressed three-wheeler vehicle was created by Toyota in 2011. The speciality about this vehicle is it has registered a record-breaking highest speed 129.2 km/h (80 mph) even if it has engine which uses only compressed air. This car was developed by the companies “Dream car workshop”. This car is nicknamed as “sleek rocket”, or “pencil shaped rocket”.

As part of the TV-show Planet Mechanics, Jem Stansfield and Dick Strawbridge converted a regular scooter to a compressed air moped. This has been done by equipping the scooter with a compressed-air engine and air tank.

In 2010, Honda presented the Honda Air concept car at the LA Auto Show.

Trains, Trams, Boats and Planes

Compressed-air locomotives are a kind of fireless locomotive and have been used in mining and tunnel boring.

Various compressed-air-powered trams were trialled, starting in 1876. In Nantes and Paris such trams ran in regular service for 30 years.

Currently, no water or air vehicles exist that make use of the compressed air engine. Historically certain torpedoes were propelled by compressed-air engines.

Source from Wikipedia