Biogas refers to a mixture of different gases produced by the breakdown of organic matter in the absence of oxygen. Biogas can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. Biogas is a renewable energy source.

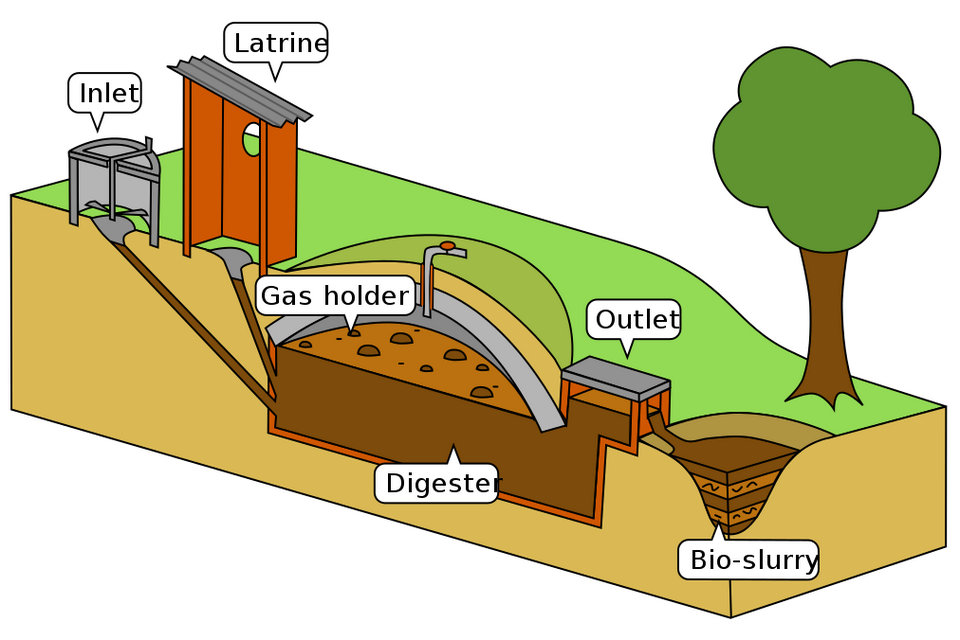

Biogas can be produced by anaerobic digestion with methanogen or anaerobic organisms, which digest material inside a closed system, or fermentation of biodegradable materials. This closed system is called an anaerobic digester, biodigester or a bioreactor.

Biogas is primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulphide (H2S), moisture and siloxanes. The gases methane, hydrogen, and carbon monoxide (CO) can be combusted or oxidized with oxygen. This energy release allows biogas to be used as a fuel; it can be used for any heating purpose, such as cooking. It can also be used in a gas engine to convert the energy in the gas into electricity and heat.

Biogas can be compressed, the same way as natural gas is compressed to CNG, and used to power motor vehicles. In the United Kingdom, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel. It qualifies for renewable energy subsidies in some parts of the world. Biogas can be cleaned and upgraded to natural gas standards, when it becomes bio-methane. Biogas is considered to be a renewable resource because its production-and-use cycle is continuous, and it generates no net carbon dioxide. As the organic material grows, it is converted and used. It then regrows in a continually repeating cycle. From a carbon perspective, as much carbon dioxide is absorbed from the atmosphere in the growth of the primary bio-resource as is released, when the material is ultimately converted to energy.

Composition and characteristics of biogas

The chemical composition of biogas depends primarily on two factors: the materials used in the digestion and the technology used for the process. With this in mind, biogas can contain between 55-70% methane, 30-45% carbon dioxide and <5% traces of other gases (considered impurities).

Its features biogas has a calorific value between 6 to 6.5 kWh / Nm 3, equivalent fuel is 0.6 to 0.65 L oil per cubic meter of biogas. Ignition temperature of 650 to 750 ° C. Critical pressure from 74 to 88 atmosphere. Critical temperature of -82.5 ° C. Density of 1.2 kg / m3. Molar mass of 16,043 g / mol.

Energy value

It depends on the composition of the gas resulting from the fermentation: the more methane it contains, the more it is energetic. For example a fermentable material rich in C and H produces a biogas containing up to 90% methane, while cellulose, poorer in C and H will produce a biogas only 55% methane (and 45% carbon dioxide)

Efficiency

IFEU studies show that in Germany, the use of biogas for local cogeneration with a gas engine is more efficient with respect to the greenhouse effect, the injection into the networks and the necessary maintenance. However, this study estimates the energy supplied to the equivalent of 5,000 liters of fuel oil per hectare per year. Replace fossil fuels and nuclear power with biogas require almost the whole surface of Germany.

The operating efficiency of heat and power cogeneration is at best 70%, or 30% of losses.

The use of heat is often seasonal and requires proximity to users and the creation of a distribution network. It is also possible to provide cold through heat absorption processes. However, this use is limited to certain regions in France.

Injection is allowed and may have an operating efficiency of 90%. The consumption of gas is also seasonal but in general the injection is possible on the networks all the year, except in some cases, a few days or weeks in summer, where the consumption is lower and thus the network is saturated. By injection, the production of biomethane in summer finds an outlet that is not always found heat cogeneration.

Many projects are in France in injection. For example, Fontainebleau, accompanied by the École Supérieure des Mines, is starting up an anaerobic digestion of 30,000 tons of horse manure per year under the project name: EQUIMETH.

Around the world, the use of biogas at the domestic level is widespread, especially in Asia

In Mali, pilot projects were conducted in isolated areas to measure how biogas can produce energy for domestic use in a sustainable way. Experience has shown that with the training of local craftsmen who can support the production of the necessary equipment (gasometer, digester) and the training of families in equipment maintenance, biogas can be a viable alternative to use of woodfuels for cooking meals and improve living conditions through other energy inputs (especially refrigeration). Pressure on wood resources has decreased and compostproduct has been used to fertilize soils. Financial support remains necessary for the implementation of the system (equipment, installation, training).

Arti, a non-governmental organization in India, is developing a simple 0.5 m3 (elevated) digester for the tropics that uses kitchen waste (rich in starch and sugars) to produce biogas. 1 kg of waste produces 400 liters of biogas in 6 to 8 hours, which is enough for about 15 to 20 minutes of cooking.

Production

The biogas is a renewable energy that can be used for heating, electricity, and many other operations that use a reciprocating internal combustion engine, such as GE Jenbacher or Caterpillar gas engines. To provide these internal combustion engines with biogas having ample gas pressure to optimize combustion, within the European Union ATEX centrifugal fan units built in accordance with the European directive 2014/34/EU (previously 94/9/EG) are obligatory. These centrifugal fan units, for example Combimac, Meidinger AG or Witt & Sohn AG are suitable for use in Zone 1 and 2.

Other internal combustion engines such as gas turbines are suitable for the conversion of biogas into both electricity and heat. The digestate is the remaining inorganic matter that was not transformed into biogas. It can be used as an agricultural fertiliser.

Biogas is produced either;

as landfill gas (LFG), which is produced by the breakdown of biodegradable waste inside a landfill due to chemical reactions and microbes, or

as digested gas, produced inside an anaerobic digester.

Projects such as NANOCLEAN are nowadays developing new ways to produce biogas more efficiently, using iron oxide nanoparticles in the processes of organic waste treatment. This process can triple the production of biogas.

Process of biosynthesis

There are three ranges of biogas production, depending on the temperature.

15-25 ° C: psychrophilic

25-45 ° C: mesophilic

45-65 ° C: thermophilic

These are the digesters mesophilic that are most used (approx 38 ° C) in temperate zones.

Landfill biogas recovery is doubly interesting because methane released into the atmosphere is a much more potent greenhouse gas than carbon dioxide (CO2) produced by its combustion.

Sources of biogas

The biogas resulting from the anaerobic digestion or digestion anaerobic waste fermentable. The most common sources of biogas come from voluntary or involuntary stocks of organic matter:

Cultures;

Landfills: their biogas content is higher or lower depending on the tightness of the operating mode The selective collection of putrescible waste allows methanization faster than discharge by using specific bioreactors (digesters)

Sewage treatment plant sludge: anaerobic digestion eliminates organic compounds and allows the plant to be more or less self-sufficient in energy;

Livestock effluents: regulations make effluent storage equipment (manure, manure) mandatory for a capacity of more than 6 months. This storage time can be used for the methanation of effluents. These are animal manure but also other agricultural waste: crop residues and silage, effluents from dairies, withdrawals from markets, turf, etc.

Effluents from agro-food industries can also be methanised. The goal is mainly to avoid the rejection of too rich organic materials, and can be accompanied by energy recovery;

The bottom of lakes and marshes: biogas is naturally produced by organic sediments that accumulate there. The use of Lake Kivu biogas was initiated more than 40 years ago and is now being developed on a large scale.

Stages of biogas production

The process of producing biogas by anaerobic digestion of organic matter is divided into four stages. This has been demonstrated by biochemical and microbiological studies carried out to date.

Stage I: Hydrolysis

To start the process of anaerobic decomposition it is necessary that the organic compounds can cross the cell wall and thus take advantage of the organic matter. Hydrolytic microorganisms produce extracellular enzymes capable of converting polymeric organic matter into soluble organic compounds. This stage is determinant in the overall speed of the biogas production process and can be affected by factors such as: temperature, pH, particle size, biochemical composition of the substrate, among others.

Stage II: Acidogenesis

The transformation of soluble organic molecules occurs in compounds that can be exploited by methanogenic bacteria (acetic, formic and hydrogen), others more reduced as (valeric, propionic, lactic and others) and certain compounds that can not be used by these bacteria (ethanol, fatty acids, and aromatics). They also eliminate any trace of oxygen present in the biodigester.

Stage III: Acetogenesis

They take advantage of compounds that can not be metabolized by methanogenic bacteria (ethanol, fatty acids, and aromatics) and transform them into simpler compounds such as acetate and hydrogen. Very special acetogenic microorganisms, called homoacetogenic, are capable of producing only acetate and can be used to maintain low partial pressures of hydrogen gas since they do not produce it.

Stage IV: Methanogenesis

The methanogenic bacteria act on the products of the previous stages and complete the anaerobic decomposition process through the production of methane. It has been shown that 70% of methane produced in biodigester is the result of the decarbolization of acetic acid, because only two genera of methanogenic bacteria can use acetate.

Biogas plants

A biogas plant is the name often given to an anaerobic digester that treats farm wastes or energy crops. It can be produced using anaerobic digesters (air-tight tanks with different configurations). These plants can be fed with energy crops such as maize silage or biodegradable wastes including sewage sludge and food waste. During the process, the micro-organisms transform biomass waste into biogas (mainly methane and carbon dioxide) and digestate.

Key processes

There are two key processes: mesophilic and thermophilic digestion which is dependent on temperature. In experimental work at University of Alaska Fairbanks, a 1000-litre digester using psychrophiles harvested from “mud from a frozen lake in Alaska” has produced 200–300 liters of methane per day, about 20%–30% of the output from digesters in warmer climates.

Dangers

The air pollution produced by biogas is similar to that of natural gas. The content of toxic hydrogen sulfide presents additional risks and has been responsible for serious accidents. Leaks of unburned methane are an additional risk, because methane is a potent greenhouse gas.

Biogas can be explosive when mixed in the ratio of one part biogas to 8–20 parts air. Special safety precautions have to be taken for entering an empty biogas digester for maintenance work. It is important that a biogas system never has negative pressure as this could cause an explosion. Negative gas pressure can occur if too much gas is removed or leaked; Because of this biogas should not be used at pressures below one column inch of water, measured by a pressure gauge.

Frequent smell checks must be performed on a biogas system. If biogas is smelled anywhere windows and doors should be opened immediately. If there is a fire the gas should be shut off at the gate valve of the biogas system.

Landfill gas

Landfill gas is produced by wet organic waste decomposing under anaerobic conditions in a biogas.

The waste is covered and mechanically compressed by the weight of the material that is deposited above. This material prevents oxygen exposure thus allowing anaerobic microbes to thrive. Biogas builds up and is slowly released into the atmosphere if the site has not been engineered to capture the gas. Landfill gas released in an uncontrolled way can be hazardous since it can become explosive when it escapes from the landfill and mixes with oxygen. The lower explosive limit is 5% methane and the upper is 15% methane.

The methane in biogas is 28 times more potent a greenhouse gas than carbon dioxide. Therefore, uncontained landfill gas, which escapes into the atmosphere may significantly contribute to the effects of global warming. In addition, volatile organic compounds (VOCs) in landfill gas contribute to the formation of photochemical smog.

Technical

Biochemical oxygen demand (BOD) is a measure of the amount of oxygen required by aerobic micro-organisms to decompose the organic matter in a sample of material being used in the biodigester as well as the BOD for the liquid discharge allows for the calculation of the daily energy output from a biodigester.

Another term related to biodigesters is effluent dirtiness, which tells how much organic material there is per unit of biogas source. Typical units for this measure are in mg BOD/litre. As an example, effluent dirtiness can range between 800–1200 mg BOD/litre in Panama.

From 1 kg of decommissioned kitchen bio-waste, 0.45 m³ of biogas can be obtained. The price for collecting biological waste from households is approximately €70 per ton.

Composition

The composition of biogas varies depending upon the substrate composition, as well as the conditions within the anaerobic reactor (temperature, pH, and substrate concentration). Landfill gas typically has methane concentrations around 50%. Advanced waste treatment technologies can produce biogas with 55%–75% methane, which for reactors with free liquids can be increased to 80%–90% methane using in-situ gas purification techniques. As produced, biogas contains water vapor. The fractional volume of water vapor is a function of biogas temperature; correction of measured gas volume for water vapour content and thermal expansion is easily done via simple mathematics which yields the standardized volume of dry biogas.

In some cases, biogas contains siloxanes. They are formed from the anaerobic decomposition of materials commonly found in soaps and detergents. During combustion of biogas containing siloxanes, silicon is released and can combine with free oxygen or other elements in the combustion gas. Deposits are formed containing mostly silica (SiO2) or silicates (SixOy) and can contain calcium, sulfur, zinc, phosphorus. Such white mineral deposits accumulate to a surface thickness of several millimeters and must be removed by chemical or mechanical means.

Practical and cost-effective technologies to remove siloxanes and other biogas contaminants are available.

For 1000 kg (wet weight) of input to a typical biodigester, total solids may be 30% of the wet weight while volatile suspended solids may be 90% of the total solids. Protein would be 20% of the volatile solids, carbohydrates would be 70% of the volatile solids, and finally fats would be 10% of the volatile solids.

Advantages

As a biofuel, it has many advantages:

reduction of greenhouse gas emissions, as noted above;

significant reduction in fine particulate emissions compared to diesel and gasoline;

reduction of certain microbes in agricultural effluents (coliforms in particular);

substitute for other exogenous energies (fossil and nuclear), source of income for the operator who saves on his energy expenses and / or, more and more sells his energy;

decrease in the carbon load of plant waste. Once digested, the waste is less harmful to the environment; the risk of biological or organic pollution is also greatly reduced, and fermentation decreases the percentage of dry matter, to reduce the volume to be transported and spread;

the manure is treated free of charge by or for farmers who recover it at the end of the cycle, after producing methane, better quality because it does not “burn” the plants, it is rid of many pathogens and all the seeds of “Weeds” that it could contain.

It can also be injected into the natural gas network after purification. This is the solution that offers the best energy efficiency, if the network is close enough to the point of production. This solution is now supported by the network operators, who are even considering 100% green gas in 2050. In France, Afsset concluded in 2009 that the injection of purified biogas into the network posed no particular health problem.

Benefits of manure derived biogas

High levels of methane are produced when manure is stored under anaerobic conditions. During storage and when manure has been applied to the land, nitrous oxide is also produced as a byproduct of the denitrification process. Nitrous oxide (N2O) is 320 times more aggressive as a greenhouse gas than carbon dioxide and methane 25 times more than carbon dioxide.

By converting cow manure into methane biogas via anaerobic digestion, the millions of cattle in the United States would be able to produce 100 billion kiloWatt hours of electricity, enough to power millions of homes across the United States. In fact, one cow can produce enough manure in one day to generate 3 kiloWatt hours of electricity; only 2.4 kiloWatt hours of electricity are needed to power a single 100-Watt light bulb for one day. Furthermore, by converting cattle manure into methane biogas instead of letting it decompose, global warming gases could be reduced by 99 million metric tons or 4%.

Applications

Biogas can be used for electricity production on sewage works, in a CHP gas engine, where the waste heat from the engine is conveniently used for heating the digester; cooking; space heating; water heating; and process heating. If compressed, it can replace compressed natural gas for use in vehicles, where it can fuel an internal combustion engine or fuel cells and is a much more effective displacer of carbon dioxide than the normal use in on-site CHP plants.

In addition to its own use in agriculture, biogas is also suitable as a contribution to an energy mix from renewable energies. This is because, on the one hand, it is capable of generating base load, which means that the biogas is continuously available, in contrast to other renewable energy sources such as wind or sun. On the other hand, biomass and biogas can be stored, which can contribute to peak energy supply. Therefore, this bioenergy source is suitable for compensating for short-term fluctuations in the electricity supply of wind and solar energy. So far, most biogas plants are operated continuously, virtually as a base load power plant. To use the energy contained the following options are available: On-site combined heat and power (CHP): Biogas is used in a combined heat and power plant (CHP) to produce electricity and heat (CHP); the electricity is fully fed into the grid, the approximately 60 percent waste heat can be used on site. Alternatively, the biogas can be fed into the supply network after appropriate treatment.

Cogeneration units

In Germany, the burning of biogas in combined heat and power plants (CHP) is the most common way of producing electricity in addition to heat to be fed into the electricity grid.

As most of the biogas revenues are generated by the sale of electricity, the heat consumer has a combined heat and power unit, which produces electricity as the main product for grid feed-in and ideally feeds heat into a local or district heating grid. An example of a district heating network is the bioenergy village Jühnde. So far, however, only a small part of the heat is used in most agricultural biogas plants for lack of heat demand on site, for example for heating the fermenter and residential and commercial buildings.

Biogas network

An alternative is the transport of biogas in biogas lines via micro gas networks. Electricity and heat production can thus take place with heat consumers.

Further types of use

Biogas can be used as almost CO2 -neutral fuel in automotive engines. Since a preparation for natural gas quality is necessary, the CO2 component must be removed as far as possible. It can be used commercially after the separation, for example in the beverage industry. So-called biomethane or bio natural gas must be compressed to 200 to 300 bar in order to be used in converted vehicles.

Trucks owned by Walter Schmid AG and the associated company Kompogas have been using biogas in Switzerland since 1995, and the first truck reached its millionth kilometer in the summer of 2010. As of 2001 also drove Migros Zurich with Kompogas and since 2002 McDonald’s Switzerland.

So far, biogas is rarely used in this way. In 2006, the first German biogas station was opened in Jameln (Wendland).

Due to the high electrical efficiencies, the utilization of biogas in fuel cells could be interesting in the future. The high price for the fuel cells, the elaborate gas purification and the in practical tests so far still short service life prevent so far a wider application of this technology.

Biogas upgrading

Raw biogas produced from digestion is roughly 60% methane and 29% CO2 with trace elements of H2S: inadequate for use in machinery. The corrosive nature of H2S alone is enough to destroy the mechanisms.

Methane in biogas can be concentrated via a biogas upgrader to the same standards as fossil natural gas, which itself has to go through a cleaning process, and becomes biomethane. If the local gas network allows, the producer of the biogas may use their distribution networks. Gas must be very clean to reach pipeline quality and must be of the correct composition for the distribution network to accept. Carbon dioxide, water, hydrogen sulfide, and particulates must be removed if present.

There are four main methods of upgrading: water washing, pressure swing absorption, selexol absorption, and amine gas treating. In addition to these, the use of membrane separation technology for biogas upgrading is increasing, and there are already several plants operating in Europe and USA.

The most prevalent method is water washing where high pressure gas flows into a column where the carbon dioxide and other trace elements are scrubbed by cascading water running counter-flow to the gas. This arrangement could deliver 98% methane with manufacturers guaranteeing maximum 2% methane loss in the system. It takes roughly between 3% and 6% of the total energy output in gas to run a biogas upgrading system.

Biogas gas-grid injection

Gas-grid injection is the injection of biogas into the methane grid (natural gas grid). Until the breakthrough of micro combined heat and power two-thirds of all the energy produced by biogas power plants was lost (as heat). Using the grid to transport the gas to customers, the energy can be used for on-site generation, resulting in a reduction of losses in the transportation of energy. Typical energy losses in natural gas transmission systems range from 1% to 2%; in electricity transmission they range from 5% to 8%.

Before being injected in the gas grid, biogas passes a cleaning process, during which it is upgraded to natural gas quality. During the cleaning process trace components harmful to the gas grid and the final users are removed.

Biogas in transport

If concentrated and compressed, it can be used in vehicle transportation. Compressed biogas is becoming widely used in Sweden, Switzerland, and Germany. A biogas-powered train, named Biogaståget Amanda (The Biogas Train Amanda), has been in service in Sweden since 2005. Biogas powers automobiles. In 1974, a British documentary film titled Sweet as a Nut detailed the biogas production process from pig manure and showed how it fueled a custom-adapted combustion engine. In 2007, an estimated 12,000 vehicles were being fueled with upgraded biogas worldwide, mostly in Europe.

Biogasmax: waste energy for environmental urban transport

Biogasmax is a European project of the 6 th Framework Program for Research and Development FP6 – 6 th Framework Program (2000-2006) of the European Commission. It is part of Europe’s initiatives to reduce its dependence on fossil fuels. Based on existing experiences in Europe, it promotes techniques and achievements demonstrating the value of using biogas as a fuel for land transport, based on the available deposits in urban areas in Europe.

This four-year project will demonstrate technical reliability and environmental, societal and financial benefits. Based on full-scale demonstrations, the project will optimize existing industrial processes and research new ones. In addition to its technical value, Biogasmax has a scouting function to reduce barriers to entry, be they technical, operational, institutional or regulatory. The knowledge gained will be disseminated throughout the European Union, especially in the new Member States.

In fact, this project does not start from a virgin situation; its members participate in innovative projects in this field, some for a long time. It is therefore a European project of proof and not of intention.

Biogasmax includes cities such as Lille in France, Stockholm and Gothenburg in Sweden, Rome in Italy, Bern in Switzerland, Torun and Zielona Gora in Poland. The project is surrounded by advanced skills in Germany (ISET in Kassel for aspects of purification and concentration of biogas, the University of Stuttgart for life cycle analysis of biomethane-fuel), transfer of skills, as well as a set of public and private partners in the countries concerned: mainly waste and energy management operators.

Most of the most successful experiments currently involving the use of biogas as fuel are represented within Biogasmax, providing a highly prolific framework for communication and action.

Biogasmax represents a perspective of the experiences: each city has located its own strategy and objectives as indicated on the website of the project. There is intense exchange between the partners, which results in a number of results and technical reports available on the Web. This visibility of the results is also accompanied by strategic documents on the evolution of biomethane (biogas adapted to engine carburation), its participation in the consideration of climate change and assistance to its consideration in urban metropolises.. These exchanges, fruitful from the inside, thus spread to the whole community concerned, as the project progressed and also through ad hoc dissemination operations.

With the acquisition of best practices, Biogasmax’s partners are able to federate the best participants and to promote reflection and actions concerning this approach.

Following Biogasmax, the European Biomethane Regions program is also promoting this energy

Measuring in biogas environments

Biogas is part of the wet gas and condensing gas (or air) category that includes mist or fog in the gas stream. The mist or fog is predominately water vapor that condenses on the sides of pipes or stacks throughout the gas flow. Biogas environments include wastewater digesters, landfills, and animal feeding operations (covered livestock lagoons).

Ultrasonic flow meters are one of the few devices capable of measuring in a biogas atmosphere. Most of thermal flow meters are unable to provide reliable data because the moisture causes steady high flow readings and continuous flow spiking, although there are single-point insertion thermal mass flow meters capable of accurately monitoring biogas flows with minimal pressure drop. They can handle moisture variations that occur in the flow stream because of daily and seasonal temperature fluctuations, and account for the moisture in the flow stream to produce a dry gas value.

Source from Wikipedia